Every organization has moments when performance slips, defects rise, or processes take longer than they should. The question is, how do you fix what’s broken without disrupting everything that works?

That’s where the DMAIC methodology comes in. Used widely in Lean Six Sigma, DMAIC provides teams with a clear, step-by-step framework for identifying the root cause of inefficiency, measuring its impact, and improving it. It’s not theory, it’s a practical, repeatable way to make any process better.

From manufacturing to IT, thousands of companies rely on the DMAIC process to make smarter decisions, reduce waste, and build consistent quality. If you’re new to Six Sigma or looking to strengthen your approach, this guide will help you understand what DMAIC really means, how each phase works, and why it continues to drive process improvement success in 2025.

What is DMAIC Methodology?

DMAIC is a practical problem-solving framework used in Lean Six Sigma to improve process efficiency and predictability.

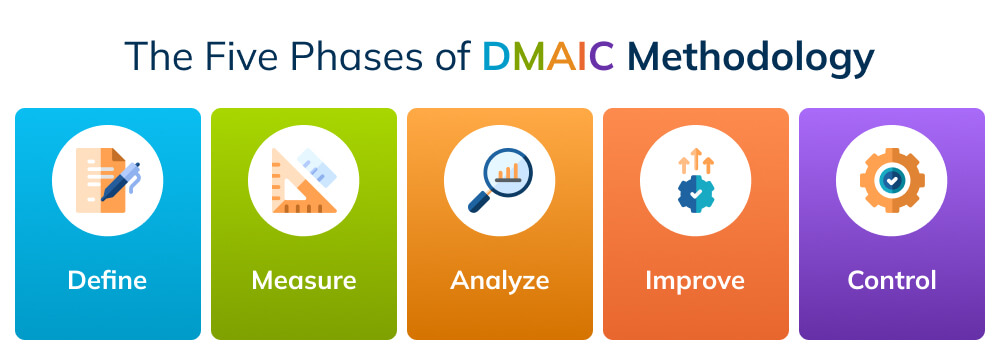

The name stands for Define, Measure, Analyze, Improve, and Control – the five phases that guide teams from identifying an issue to sustaining long-term improvements.

Unlike one-time fixes, the DMAIC process follows a disciplined path. It begins by defining the problem and customer requirements, measuring what’s happening in real time, analyzing the data to find the root cause, improving the process with targeted actions, and finally, putting controls in place so the gains don’t slip back.

What makes DMAIC powerful is its balance between data and human judgment. It helps teams move beyond assumptions by using facts to uncover where effort, cost, or quality is being lost. That’s why the Six Sigma DMAIC approach has become the foundation for process excellence, whether it’s reducing production errors, shortening service turnaround times, or optimizing customer experience.

The Five Phases of DMAIC Methodology

The DMAIC methodology in Six Sigma follows a structured, data-driven process – Define, Measure, Analyze, Improve, and Control. Each phase of the DMAIC model helps teams identify inefficiencies, apply the right DMAIC tools, and sustain long-term quality improvements. Together, they make the Six Sigma DMAIC process a proven framework for achieving consistent performance.

Define

In this first step of DMAIC methodology, the team must clearly define the issues and the action plan necessary to attain the desired results in this initial step toward process improvement. The goal of this phase of DMAIC is to define the problem statement and develop a strategy for improvement. This phase is all about defining the issue and the improvement activity’s objectives. The most essential objectives are obtained from the clients because customer satisfaction is the primary objective of lean six sigma. So, project managers identify the issue to be addressed. To do so, one must first understand the problems as a whole and know the preferences of the customers.

Then they will need to define a problem statement for this and check if the issue reported is relevant by looking at the data available. As a result, they will be able to:

- Prioritize the issue into priorities

- Recognize the areas where it will influence

- Know the available resources

Once they figure out the problem statement and then outline the work process, they can start working on the project. The following stages ensure that the process is moving in the right direction.

The most commonly used DMAIC Tools in the “define” phase is Project Charter.

The project charter is the initial step in every six sigma project and one of the most crucial components. The document includes a summary of the project and serves as a contract between management and the six sigma team for the project’s projected outcome. Teams use the charter to define the process issue being addressed, the reason for doing so, and what “success” looks like for those working on it. Project Charter also helps to clarify what has not been discussed.

Measure

The goal of this phase is to gather data from the process and determine the current quality level. In this stage of DMAIC methodology, the team measures the existing system by defining valid and reliable metrics which will in turn help in tracking progress toward the goal. They must measure and monitor the project’s development and performance as soon as one begins working on it.

They must keep a close eye on the project and write down the “current stage” for the first assessment and use it as a baseline for the subsequent evaluations. It is a benchmark against which the project’s progress will be measured.

They may use this phase to figure out a means to collect as much measurable data as possible since it will be needed to analyze the core cause of the problems and their consequences. Constant updates from the team will be beneficial in this regard. One thing to keep in mind when gathering data is the source. Data must be accurate and come from a reputable source.

To make them more effective, they may make regular updates to the data in the workflow tools, such as a project charter.

The most commonly used DMAIC Tools in the “measure” phase are:

Histogram

It is a type of bar chart that visualizes both attribute and variable data of a product or process and helps users show the different distribution of data and amount of variation within a process. So, it should be designed properly to easily utilize and understand those working in the operation process. Histograms can show the distribution of a process that is going smoothly over time. So, any fluctuation in that process can be immediately observed when histograms are produced on a regular basis. This is a significant benefit for businesses since it allows them to identify and address process variance immediately.

Pareto Chart

A Pareto Chart is a combination of a bar and line table that visually summarizes a set of data. The information might be related to things like cost, time, and mistakes. A Pareto chart helps to measure the cumulative impact of the defects. Now, the cumulative impact is the result of a defect occurring over a long time.

The pareto chart helps and offer a clearer understanding of the problems that must be addressed first, which helps to deliberate and arrange for the right and necessary procedures or actions to be performed in the event of a fault.

Analyze

The major goal of this step in DMAIC methodology is to locate the source of the issue. Then, one may utilize the information gathered in the previous phases to figure out what’s causing it. The team manager keeps a close eye on the entire process along with the data. It is critical to assess the progress. So for this, make a list of the difficulties and concerns that arise from the data and observations. The team may contribute by expressing their perspectives and adding value to the process. Because lean six sigma focuses on removing waste from processes, the analysis includes analyzing the procedure in terms of:

1. Time: How efficiently project participants use their time. Are there any delays as a result of too extended breaks? Is there any factor that is causing the project to fall behind schedule?

2. Value: Is the project on track to meet the customer’s expectations? How does it provide value in terms of efficiency and product quality?

3. Value Stream Mapping: VSM is a technique for visualizing the flow. They may use the data to map the process and pinpoint the locations where waste processes are happening. It will allow the team to make better judgments about whether or not to add or remove a process step.

The most commonly used DMAIC Tools in the “analyze” phase are:

Fishbone- Diagram

During problem-solving, each team member has a different perspective on the root cause of the problem or question. The fishbone diagram collects all items and thoughts then uses brainstorming techniques to analyze and identify the most powerful underlying cause for that problem. It presents the possible causes using a graphic format. The core problem is placed at the head of the fish, then the different processes and sub-processes that may be responsible for the problem are noted in the bones of the fish.

5 Whys

This is a very interesting tool in the analysis phase. So to find the main cause of an issue, they should constantly ask the question “Why” (five is a decent rule of thumb). The actual cause of one problem will often lead to a new question. Despite the name “5 Whys,” one may discover that they need to ask the question fewer or more times than five times before they uncover the issue that is causing the problem.

Manufacturing: Cutting Defects in Automotive Rubber Weather StripsWhat they did: An Indian auto-components maker used the Six Sigma DMAIC cycle to reduce high rejection rates on door weather strips. DMAIC highlights:

Results you can quote:

|

Improve

In this phase of DMAIC methodology, after gathering the data and determining the root of the problem, the team member must devise a plan to address it. Using the data and the analysis report, the team at this stage seeks to improve the entire process. Now, the enhancements are introduced appropriately to get the intended benefits. As a result, they will need to put together a solid plan of action and assemble a team capable of coming up with creative answers. Proposing and choosing a solution to improve the system is the focus of this phase. This is the phase at which the team must become innovative in order to identify new methods to do things better, cheaper, or faster. The team addresses the root causes directly with an improvement based on the identified root causes.

One thing to keep in mind is that solutions must be feasible. They should be simple to execute and will not significantly increase the project’s expense. Other project restrictions, such as available workforce and technical assistance, must also be considered.

After figuring out the solutions, it’s time to put them into action and it is required to track and measure the progress. Now, to make things simpler, develop a list of the modifications that result in a better overall procedure.

The most commonly used DMAIC Tools in the “improve” phase are:

Countermeasures Matrix

A Countermeasures Matrix outlines the problems, identifies their causes, its fixes (countermeasures), and implementation priorities for an issue. Here, prioritization is determined by the team, ranking the recommended action items based on their importance or feasibility. This matrix acts as a source of information for creating an action plan.

Action Plan

Most improvements will need a strategy to ensure that they are implemented appropriately and that their effectiveness can be measured. So an action plan is very important. It is a strategy that helps improve the end products. An effective action plan will include questions like:

- What are the countermeasures?

- How to do them?

- Who will do them?

- When will they begin and end?

- How will they be measured?

Control

The fifth stage of the DMAIC methodology is control, and it assures that the changes produced will last. It must be ensured that the problems do not occur again and the entire process adheres to the lean six sigma principles. Any deviations should be recorded and brought to the attention of the team. The team implements the solution and gives the ownership of the new, enhanced process to the responsible owner. They create a control strategy to monitor the ongoing performance and employ statistical methods to monitor the new process’s stability.

The team members can develop a monitoring algorithm that allows them to choose the various levels at which the process will function. They may also strategize the action plan to ensure that the gains are evident at these stages. They may also urge team members to keep the data up to date and add the progress at each level. This record is useful during the control phase. To find any issues with your DMAIC implementation, use this record.

The most commonly used DMAIC Tools in the “control” phase is:

Control Chart

In this phase, control charts are the most widely used tool. It helps in identifying the causes for variation in the new process, as well as the identification of corrective measures that must be taken before there are too many errors. This helps eliminate the requirement for product rework or additional product costs to repair an offering. So this was about the five phases of DMAIC methodology and the frequently used tools in these phases.

Initially, DMAIC was known as a method for reducing variation, but now the application of DMAIC can be considered a well-known mechanism for problem-solving and process improvement. Now, let us talk about some of the benefits of the DMAIC methodology.

Benefits of DMAIC Methodology

The DMAIC methodology isn’t just a tool for process improvement; it’s a disciplined approach to thinking, acting, and leading change. By consistently applying the DMAIC process, teams gain more than efficiency; they build a culture of continuous improvement where data, not assumptions, support every decision.

Here are some of the most valuable benefits of DMAIC in today’s quality-driven organizations:

Structured Approach

DMAIC is a systematic technique that gives a road map for finding solutions. This enables us to solve problems from beginning to end while producing bottom-line results. DMAIC also offers an analytical approach, allowing the use of the data gathered. This helps the business ensure accurate baselines.

Faster Cycle Times

DMAIC software removes the friction from improvement, resulting in shorter improvement cycles and a quicker route to positive change. Because DMAIC improves communication, visibility, and responsibility, there is less downtime between phases in the improvement cycle. The faster each changes are implemented from beginning to end, the sooner the benefits are realized and move on to the next initiative.

Better Collaboration

DMAIC improves the collaboration of the entire team. One of the most difficult aspects of structured improvement is keeping everyone on the same page and informed about the cycle’s progress. This is especially challenging when the team consists of individuals from several functional areas who use distinct processes, terminology, and management styles.

More Impact From Improvement

With a knowledge repository in place, each DMAIC cycle may start with a review of what has previously worked successfully or failed. Teams get an advantage in terms of improvement by making more informed, data-driven decisions that result in more effective improvements. DMAIC software is useful because each improvement has the maximum, long-term impact.

Increased Productivity

Because the strategy is so systematic and requires comprehensive documentation, it helps to improve their problem-solving approach and efficiency constantly. DMAIC allows a business to quantify improvements and find answers to complex problems.

Improve the Overall Process

Then, it’s time to apply the DMAIC technique to improve the process. It aids in the identification of the problem’s fundamental cause and allows for the brainstorming of relevant solutions to the problems. The main goal of the DMAIC methodology is to improve the overall process. So these were just some of the benefits of the DMAIC methodology.

The DMAIC methodology gives structure to creativity and discipline to improvement. It helps teams ask better questions, find clearer answers, and create measurable change, making it one of the most powerful frameworks in Lean Six Sigma and modern quality management.

DMAIC vs DMADV

While both DMAIC and DMADV are integral parts of Six Sigma methodology, they serve different purposes within process improvement. The DMAIC process is ideal for refining, controlling, or optimizing an existing workflow. It helps teams uncover inefficiencies and apply data-driven solutions to improve performance.

On the other hand, DMADV, another branch of Six Sigma DMAIC principles, is used when a process must be designed or redesigned from scratch to meet new goals or customer expectations.

Understanding the difference between DMAIC and DMADV ensures teams choose the right approach: one focuses on enhancing what exists, while the other builds something entirely new.

| Aspect | DMAIC | DMADV |

| Full Form | Define – Measure – Analyze – Improve – Control | Define – Measure – Analyze – Design – Verify |

| Primary Focus | Improving an existing process or product | Designing a new process or product from scratch |

| Goal | Reduce variation, eliminate defects, enhance efficiency | Create a process that meets customer requirements perfectly the first time |

| Outcome | Optimized existing process | Newly designed process built to Six Sigma standards |

| Use Case Example | Reducing defect rate in a manufacturing line | Designing a new digital onboarding system for customers |

Conclusion

The DMAIC methodology remains the foundation of Lean Six Sigma and modern process improvement. It gives organizations a disciplined way to identify problems, measure performance, and implement lasting solutions, not through assumptions but through data and teamwork.

Across industries, the Six Sigma DMAIC process helps professionals achieve operational consistency, eliminate waste, and deliver measurable business impact. Whether the goal is reducing defects, shortening lead times, or improving customer satisfaction, DMAIC offers a proven roadmap for results.

For professionals who want to lead improvement initiatives with confidence, learning how to apply DMAIC in Six Sigma projects is a career-defining skill. Take the next step in your quality journey with Invensis Learning’s Quality Management Certification programs, designed to help you master practical tools, solve complex business challenges, and make process excellence a habit.