Resource management is a make-or-break factor in construction projects. Without it, many projects confront delays, cost overruns, and quality compromises. In fact, as highlighted in Invensis Learning’s guide on using decision flowcharts for project management, 23% of failed large-scale construction projects are tied to slow or poor decision-making and delayed stakeholder approvals. A clear signal that not just resources, but timely decisions, are vital for keeping construction timelines and budgets on track. Given these stakes, mastering both resource allocation and decision-making processes has never been more essential.

This comprehensive guide explains what construction resource management is, outlines a 7-step process for implementing it, and highlights the key benefits of doing it correctly. We’ll draw on research and industry best practices to help you optimize labor, materials, equipment, and finances so your construction projects stay on schedule and within budget.

What Is Construction Resource Management?

Construction resource management is the process of planning, allocating, and overseeing all the resources needed for a construction project. These resources include materials, labor, equipment, facilities, time, and finances. In essence, it ensures the right resources are available at the right time and used efficiently to meet project goals. Project managers monitor and adjust resource usage throughout the build to keep work on track and within budget.

Effective resource management is vital because construction projects involve many moving parts and constraints. Without a solid plan, tasks may receive either too few or too many resources, resulting in bottlenecks or idle time. For example, imagine a project where steel deliveries arrive two weeks late, crews are left waiting, equipment sits idle, and schedules quickly fall behind. On the other hand, if too many laborers are assigned before the foundation is ready, payroll costs rise while workers have little to do. Proper resource management prevents these situations by aligning materials, labor, and equipment with the project timeline, maximizing productivity and minimizing waste.

Types of Resources in Construction Projects

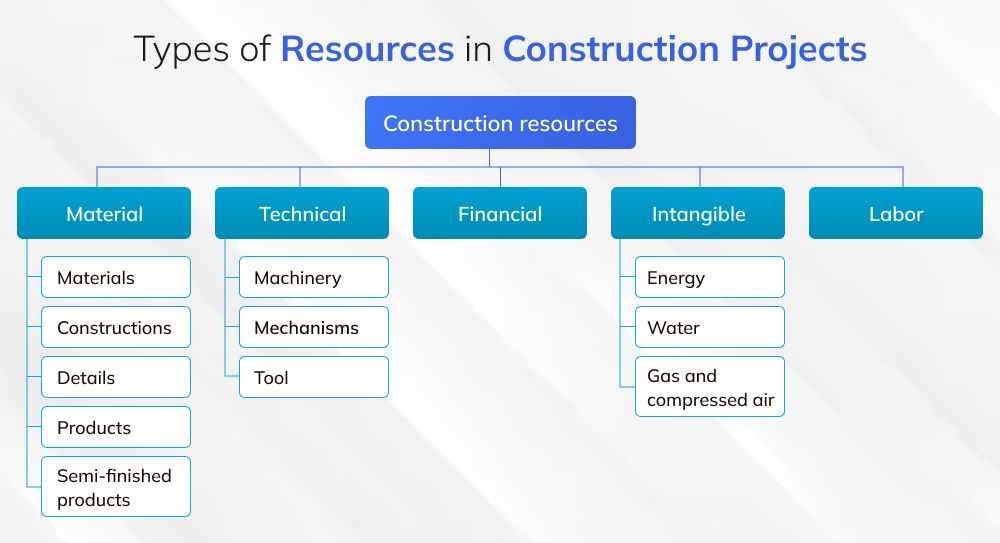

Construction projects depend on a variety of resources that must be carefully managed together:

- Material Resources: These include raw materials, semi-finished products, and prefabricated components such as concrete, steel, bricks, lumber, and other construction details. Choosing the right quality at the right cost ensures durability and efficiency.

- Technical Resources: This category covers the machinery, mechanisms, and tools required on-site. From cranes and excavators to power tools, having the right equipment at the right time keeps work flowing smoothly.

- Financial Resources: Funding is crucial for covering materials, equipment, labor, and other project expenses. Proper financial planning ensures the project remains on budget and can handle unexpected expenses.

- Intangible Resources: Elements like energy, water, gas, and compressed air support daily operations. Though less visible, they are vital for running equipment and maintaining working conditions.

- Labor Resources: The workforce includes engineers, project managers, skilled trades, and general laborers. As the driving force behind all activities, they transform plans and materials into completed structures.

Together, these resources create the foundation for successful construction management, where efficiency and balance are key.

Understanding these resource types helps a project manager anticipate needs and constraints during the planning phase. Next, we’ll walk through a step-by-step process to manage all these resources effectively.

The 7-Step Construction Resource Management Process

Resource management in construction requires a structured approach. Below is a 7-step process you can follow to plan and control resources throughout a construction project. This process starts in the early planning stages and continues through project execution and close-out, ensuring you have the right resources at the right time.

1. Conduct a Material Takeoff Analysis

The first step is to identify the materials the project will need and their corresponding quantities by performing a material takeoff. A material takeoff (MTO) is a comprehensive list of all materials required to complete the project, derived from the architectural and engineering plans. In this step, you go through the construction drawings and quantify each material. For example, how many cubic yards of concrete, how many steel beams of each size, how many bricks or tiles, etc. This ensures you know precisely what and how much to procure for the build.

By compiling an accurate material takeoff, you create the foundation for both the project’s procurement plan and its cost estimate. This prevents material shortages that can halt work, and also avoids ordering excessive materials that would go to waste. In short, material takeoff analysis helps “measure twice” so you only have to build once. It is considered one of the most essential documents for project success, as errors here can disrupt the budget and schedule in the long run.

Practical tips for this step:

- Break down the project into its components; foundations, structural frame, walls, roof, etc., and list all the materials needed for each.

- Use the drawings to measure lengths, areas, and volumes e.g., length of pipes, square footage of drywall to calculate material quantities accurately.

- Double-check unusual or custom materials, and consider waste factors (some extra material for cuts, spillage, etc.).

- Have a second person review the takeoff, since mistakes in this document can ripple through the project.

To make this process more efficient, many contractors now use digital takeoff tools such as Bluebeam Revu or PlanSwift. These platforms allow you to measure directly from drawings, generate quantities automatically, and reduce human error. Leveraging such tools not only saves time but also increases accuracy in procurement planning.

2. Define the Scope of Work and Resource Requirements

With the materials quantified, the next step is to clearly define the project’s scope and the resources required to execute it. This involves writing a detailed Scope of Work (SOW) document that outlines all the work activities, deliverables, and responsibilities involved in the project. For each primary task or phase of work, determine the resources (labor, equipment, materials, and time) required to complete it.

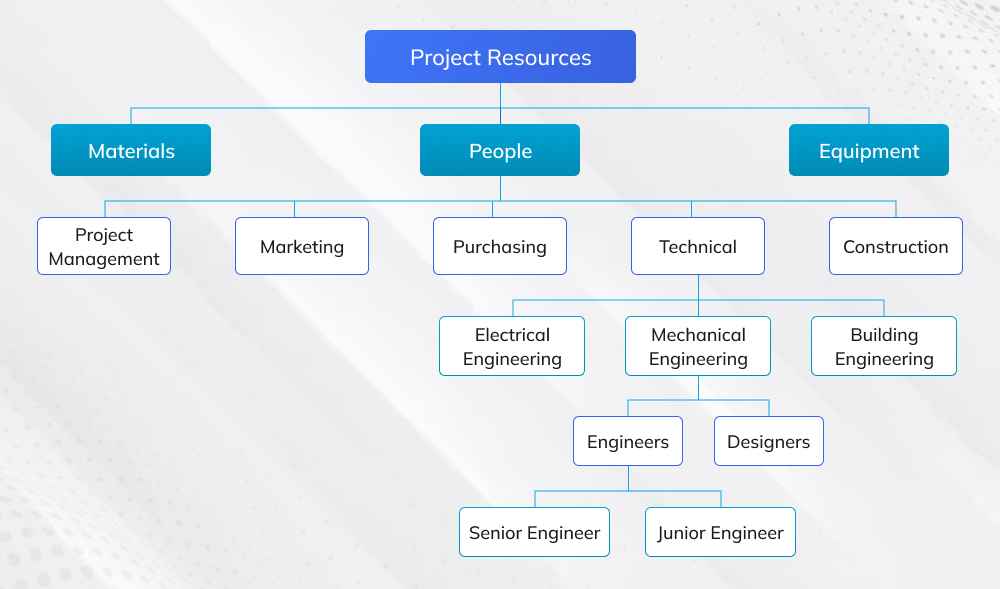

In this step, it’s helpful to create a Resource Breakdown Structure (RBS) a hierarchical list of all resources by category (labor, materials, equipment, etc.) mapped to the project scope. For example, if the project includes concrete work, the RBS would list the crews (laborers, foreman), materials (cement, rebar, formwork), and equipment (mixers, vibrators) needed for that scope. This ensures no critical resource is overlooked. As one study advises, having a clear scope and itemized resource requirements helps everyone share a common understanding of what’s needed for each task.

By validating the scope of work and resources early, you set realistic expectations. You’ll know how many carpenters, electricians, or operators you need and when; what key materials must be ready; and which equipment must be available or reserved. This step is essentially about planning “who and what” is needed for each part of the project. It provides the baseline for scheduling and budgeting in subsequent steps.

3. Estimate Costs and Create a Resource Budget

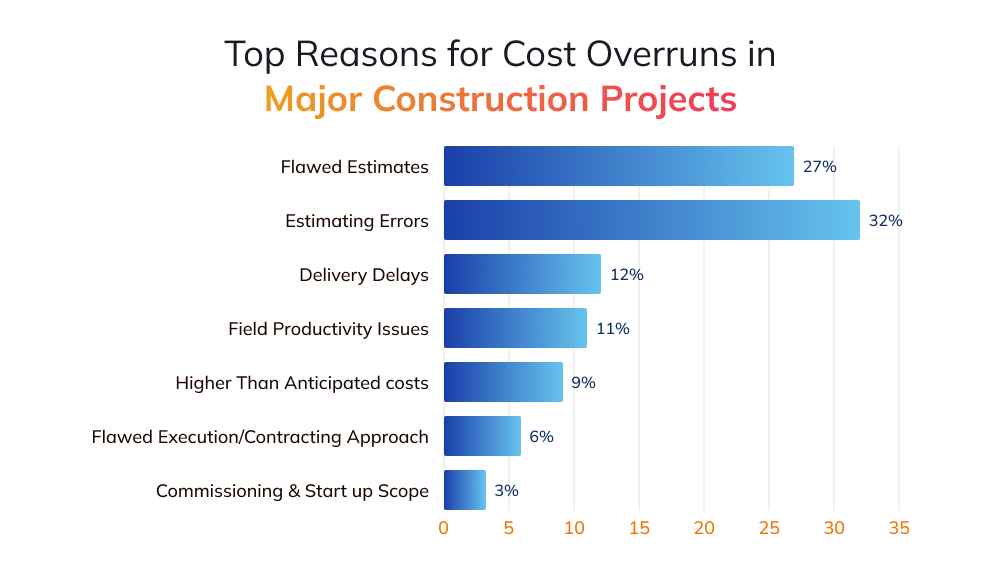

Once you know the scope and resource quantities, the next step is to estimate the costs of those resources and develop a comprehensive project budget. Failing to accurately estimate resource costs is a significant source of budget trouble in construction. Recall that underestimating labor or materials accounts for a large share of overruns. To avoid this, carefully forecast the cost of each resource category:

- Labor Costs: Estimate the work hours required for each role/trade and apply appropriate wage rates including overtime, benefits, etc. For example, calculate how many hours of an electrician the project needs and what that will cost.

- Material Costs: Use the material takeoff quantities and get current prices for each material. Don’t forget to include delivery/freight costs and potential waste or spoilage allowances.

- Equipment Costs: If renting equipment, get rental rates for the needed duration. If owned, account for fuel, maintenance, and depreciation over the project. Include any equipment mobilization costs to bring machines to the site.

- Subcontractor Costs: If parts of the scope are subcontracted (e.g. plumbing, HVAC), gather quotes from subs or use historical data to estimate those packages.

- General Conditions/Overhead: Estimate site management costs such as site office, utilities, permits, insurance, and contingency funds.

With these estimates, build the construction budget by summing up all costs and adding appropriate contingency reserves. It’s wise to attach costs to the project’s tasks and timeline. This becomes your cost baseline against which actual spending is tracked. Ensure the budget is realistic and slightly padded for unforeseen expenses, as construction inevitably encounters surprises e.g., sudden material price increases or productivity delays.

Cost-estimating software like ProEst, Sage Estimating, or even Buildertrend can support this step by generating detailed budgets, comparing vendor quotes, and linking costs to schedules. Using construction project management software to centralize estimates ensures transparency and consistency while making adjustments easier as project conditions change.

4. Secure and Acquire Necessary Resources

With the plan and budget in place, you must now secure the actual resources needed to execute the project. This step is about acquisition making sure all required resources are available when work begins, and throughout the project timeline. Several activities happen here:

- Procure Materials: Place orders for materials well in advance so they arrive on site as needed. Long-lead items should be ordered early to avoid delays. It’s often beneficial to acquire critical materials before construction starts, if storage allows, to buffer against supply chain delays. For example, long-lead procurement often applies to structural steel, custom HVAC units, or specialized prefabricated components, which can take weeks or even months to manufacture and deliver. This prevents delays in critical path activities like framing or mechanical systems setup.

- Hire or Assign Labor: Ensure the necessary workforce is in place to meet the requirements. This may involve hiring additional crew members or mobilizing teams from other projects. If specialized skills are required that your team lacks, you may need to subcontract or train staff in advance. Make sure labor availability aligns with the project schedule.

- Rent or Move Equipment: Arrange for any heavy machinery or equipment that you need to rent or move. This could mean scheduling rentals for the periods you need certain machines or relocating company-owned equipment to the site. Also, secure any permits or certifications required to operate equipment and ensure operators are available and certified.

- Prepare Facilities and Site: Set up on-site facilities, including trailers, storage areas, utilities, and safety infrastructure (such as fencing and signage), before major work commences. Also, obtain any required permits or approvals from authorities for using resources.

5. Allocate and Schedule Resources

With resources in hand, the next step is to allocate them to specific tasks and timeframes. This is where you develop a detailed resource-loaded schedule for the project. Essentially, you map out when and where each resource will be used throughout the project, aligning with the project timeline.

Key actions in this step:

- Integrate Resources into the Project Schedule: Take your project schedule which lists tasks, durations, and sequencing, and assign resources to each task. For example, Task A will have 5 carpenters for 2 weeks, requiring X cubic yards of concrete on Day 3, and a crane on Day 4. Scheduling software or Gantt charts are helpful to visualize this. Ensure that resource usage doesn’t exceed availability if Task B and Task C both need the same specialist or piece of equipment at the same time; you have a conflict to resolve.

- Optimize for Efficiency: Look for ways to stagger or overlap activities to use resources efficiently. For instance, if one crew can start work in Area 1 while another is finishing in Area 2, it avoids having a crew idle. Ensure that bottlenecks are minimized if a critical piece of equipment is needed for multiple tasks; schedule those tasks in sequence rather than concurrently to avoid competition for the machine.

- Level the Workload: Use techniques like resource leveling or smoothing. If one week requires 50 workers and the next only 10, consider adjusting some activities to balance labor demand more evenly. This prevents overworking the team one week and underutilizing them the next.

- Communicate the Plan: Ensure that all team members, subcontractors, and suppliers are informed of the resource allocation schedule. Everyone should know when their contribution is expected. This helps avoid confusion such as materials showing up early with no place to store them, or a crew arriving on site before they can actually start work.

Specialized project scheduling software such as Primavera P6 or Microsoft Project is widely used to build resource-loaded schedules. These tools let managers visualize dependencies, resolve conflicts, and update allocations in real time. They also integrate well with cost and progress tracking systems, making them ideal for large or complex projects.

| Case Study

For instance, Skanska applied BIM-integrated resource allocation software on a large-scale project, resulting in a 15% reduction in resource waste, a 10% boost in efficiency, and a 5% drop in costs. This case highlights how tech-enabled monitoring and cross-functional coordination drive measurable gains. |

6. Track Resource Utilization and Adjust as Needed

During execution, construction managers must continuously track resource utilization to keep projects on track. Industry research shows that 98% of large construction projects experience cost overruns or schedule delays, with average budget increases around 80% and timeline slippages of about 20 months. This underscores the importance of monitoring labor hours, equipment usage, and material consumption against the plan using software or spreadsheets to spot variances early. For example, higher-than-expected material use or excessive labor hours can signal inefficiencies. Regularly comparing actual versus planned usage helps identify underutilized equipment, overworked resources, or subcontractors falling behind. Managers can then reallocate crews, reschedule tasks, or arrange additional equipment as needed.

Construction projects are dynamic, so adaptability is crucial. Scope changes, weather delays, or design updates require re-estimating and updating resource plans promptly. By continuously reviewing utilization and resolving conflicts or bottlenecks, managers ensure resources are optimized, costs controlled, and schedules maintained. This proactive oversight reduces waste, prevents minor issues from escalating, and strengthens risk management by catching shortages or delays before they seriously affect project delivery.

7. Review, Learn, and Improve (Post-Project)

While the active project may be finished, the resource management process isn’t truly complete until you review the outcomes and extract lessons. In this final step, conduct a post-project review to prevent poor performance:

- Analyze Performance vs. Plan: Compare the planned resource usage (budgeted costs, scheduled hours, etc.) to the actual figures at project completion. Identify areas of significant variance. For example, perhaps the project used 10% less concrete than expected (indicating efficient use or overestimation) but 15% more labor hours (indicating lower productivity or underestimation).

- Document Key Learnings: Determine why those variances occurred. Maybe certain work took longer due to a learning curve, or maybe you found a way to optimize material use that saved money. Document these insights. For instance, “Crew A’s productivity was higher when we staggered their start times by 2 hours to share equipment” or “The prefabricated materials reduced on-site waste significantly.” These notes are valuable for future projects.

- Capture Best Practices and Areas for Improvement: Highlight what worked well in resource management did a new scheduling software help coordinate teams better? Did weekly coordination meetings with subcontractors prevent resource conflicts? Also be frank about what could improve perhaps there were communication gaps or the need for more buffer in the schedule. This honest assessment will help refine resource planning next time.

- Feedback to Stakeholders: Share relevant insights with the team, company management, or owners as appropriate. If you saved money through efficient resource use, that’s a success story to replicate. If client changes caused major resource issues, that’s something to communicate for better change management in the future.

Note: Organizations can also strengthen this step by maintaining a lessons-learned repository. A centralized database or knowledge hub where insights, best practices, and pitfalls from completed projects are recorded. This ensures that valuable experience is not lost and can be easily referenced when planning future projects, leading to continuous organizational learning.

| Case Study – The Eiffel Tower

A classic example of construction resource management can be seen in the building of the Eiffel Tower (1887–1889). The project involved assembling over 18,000 prefabricated iron components, each calculated to a tenth of a millimeter before being transported and fitted on-site. The workforce ranged between 150–300 laborers, overseen by engineers experienced in large-scale metal viaduct projects. To manage resources effectively, foundations were reinforced with concrete blocks and waterproof metal caissons, ensuring structural stability. This meticulous planning and coordination of labor, materials, and technical resources enabled the tower to be completed within just 22 months, a remarkable achievement for its scale and time. |

Benefits of Effective Construction Resource Management

Implementing a robust resource management process isn’t just about avoiding problems, it creates measurable advantages for construction firms and their clients. When labor, equipment, and materials are planned and monitored effectively, projects run more smoothly, profit margins improve, and client satisfaction rises. Below are some of the most significant benefits, supported by industry data and digital trends reshaping the field.

1. Optimized Efficiency and Resource Utilization

Sound resource management ensures materials, equipment, and labor are used to their fullest potential. Deliveries are timed to arrive just when needed, machinery is scheduled for consistent use, and crews stay engaged without idle time. This alignment directly boosts productivity and reduces waste. McKinsey research indicates that poor resource planning can waste up to 20-45% of construction costs through inefficiencies and rework. Effective resource allocation prevents these losses while ensuring steady project progress.

2. Cost Control and Budget Reliability

Because efficiency, productivity, and cost are interlinked, well-managed resources naturally reduce expenses. Avoiding surplus orders, rework, and extended equipment rentals translates into significant savings. Strategic planning also enables bulk purchasing and better control of labor costs. Most importantly, careful tracking allows early detection of overspending. Given that 98% of large projects face cost overruns averaging 80% above budget, strong resource planning is a competitive advantage that safeguards profitability and builds client trust.

3. Improved Quality and Timely Delivery

Having the right people, materials, and equipment available at the right time directly impacts both quality and schedule. Skilled labor supported by proper tools delivers work to specification, while timely adjustments prevent bottlenecks. For instance, if a critical piece of equipment fails, proactive managers can quickly reallocate or replace it to keep the schedule intact. Studies show over 54% of contractors report schedule delays due to resource shortages, underscoring the need for disciplined planning.

4. Risk Mitigation and Adaptability

Resource management doubles as risk management. By forecasting needs and monitoring usage in real time, managers can anticipate shortages or conflicts and resolve them before they escalate. Digital tools strengthen this adaptability: AI-driven planning platforms predict labor and material demand, BIM integration provides a single view of resources across the project lifecycle, and IoT-enabled equipment tracking ensures machines are deployed efficiently. These innovations not only reduce risk but also build resilience against disruptions such as weather, supply chain delays, or scope changes.

5. Stronger Collaboration and Client Satisfaction

Clear resource plans foster transparency and communication among managers, subcontractors, and suppliers. A centralized, digital resource map acts as the “single source of truth,” minimizing disputes and aligning all stakeholders. This coordination improves execution and, ultimately, client satisfaction. Delivering on time and within budget consistently builds trust, repeat business, and a stronger reputation, critical differentiators in the competitive construction sector.

Conclusion

Construction resource management is the foundation of successful project delivery. By planning, acquiring, and allocating resources effectively, managers can cut waste, prevent delays, and ensure projects finish on time and within budget. In an industry where margins are thin and risks are high, those who master resource management consistently achieve better outcomes, higher productivity, improved quality, and stronger client trust.

Looking forward, the future of construction will be shaped by digital transformation and sustainability. AI-driven planning, BIM integration, and IoT-enabled equipment tracking are already turning resource management into a data-driven discipline. This makes it not just a project necessity but a strategic advantage. To build these capabilities, consider the PMI Construction Professional (PMI-CP) certification, which equips professionals to manage modern construction challenges with confidence.