In an era where organizations face relentless pressure to deliver faster, cheaper, and better, one methodology has proven its enduring value across industries and decades: Lean Project Management. Born on Toyota’s factory floors in the 1950s, Lean principles have transcended manufacturing to revolutionize how teams manage projects, eliminate inefficiencies, and maximize customer value in 2026.

The statistics tell a compelling story. Organizations that successfully implement Lean methodologies report 25-35% reductions in project cycle time, 20-30% decreases in operational costs, and significant improvements in quality and customer satisfaction. As we navigate the complexities of hybrid work environments, rapid digital transformation, and rising customer expectations, Lean Project Management offers a proven framework to cut through complexity and focus on what truly matters.

But Lean is far more than a set of tools or techniques; it represents a fundamental shift in how we think about work. Instead of accepting waste and inefficiency as inevitable, Lean challenges us to question every activity: Does this add value for the customer? If not, why are we doing it? This relentless focus on value creation and waste elimination separates high-performing organizations from those struggling to keep pace.

In this comprehensive guide, we’ll explore the five core principles that underpin Lean, identify the eight types of waste that drain project resources, and demonstrate practical applications across industries. Whether you’re a project manager seeking to improve team efficiency, a business leader looking to transform operations, or a professional curious about Lean methodologies, you’ll discover actionable insights to immediately apply in your work.

Table of Contents:

- What Is Lean Project Management?

- The Five Core Principles of Lean Project Management

- The Eight Types of Waste (Muda) in Project Management

- Practical Application: Implementing Lean in Your Projects

- Conclusion

- Frequently Asked Questions

What Is Lean Project Management?

Lean project management is the application of Lean principles (originating from the Toyota Production System) to the planning, execution, and improvement of projects. Instead of measuring success by how many tasks are completed or how busy people appear, Lean project management focuses on one thing: maximizing customer value while minimizing waste.

In practical terms, Lean project management means you:

- Define value strictly from the customer’s point of view

- Expose and remove waste in how work flows through the project

- Deliver in smaller, faster increments instead of big-bang releases

- Build quality in from the start instead of relying on inspection at the end

- Treat improvement as ongoing, not as a once-a-year initiative

Compared to traditional project management, which often centers on upfront plans, phase gates, and adherence to scope, Lean project management is more adaptive and evidence-based. Plans still matter, but they are treated as hypotheses to be tested against real customer feedback and actual flow of work, not as fixed scripts.

Key characteristics of Lean project management:

- Value-driven planning: Scope, milestones, and deliverables are prioritized based on customer value, not internal preferences.

- Flow-focused execution: Teams manage work-in-progress, reduce handoffs, and tackle bottlenecks to shorten cycle time.

- Pull-based work management: Work is “pulled” when capacity and prerequisites are ready, instead of being “pushed” based on optimistic schedules.

- Visual management: Boards, dashboards, and value stream maps make status, bottlenecks, and waste visible.

- Continuous improvement (Kaizen): Every project is a vehicle to refine processes, not just deliverables.

When done well, Lean project management turns one-off efforts into a repeatable system that reliably delivers faster timelines, lower costs, fewer defects, and greater stakeholder satisfaction.

The Five Core Principles of Lean Project Management

Lean Project Management rests on five interconnected principles that guide decision-making, resource allocation, and continuous improvement. Mastering these principles transforms how teams approach projects, shifting from activity-focused to value-focused thinking.

1. Define Value from the Customer’s Perspective

The first and most crucial Lean principle challenges a fundamental assumption: that we truly understand what customers value. Too often, project teams define value based on internal assumptions, technical preferences, or what’s easiest to deliver rather than genuine customer needs. Lean demands that we start with the customer and work backward.

Defining value requires deep customer engagement, not just surveys or focus groups, but genuine dialogue that uncovers underlying needs, pain points, and desired outcomes. What problems are customers actually trying to solve? What would make their lives or work significantly better? What would they willingly pay for?

In the project management context, this principle means constantly asking: “Does this feature, deliverable, or activity create value that the customer recognizes and appreciates?” A beautifully designed technical solution that doesn’t address real customer needs represents waste, regardless of how much effort went into creating it. Conversely, even simple solutions that directly address customer pain points create enormous value.

Practical Application: Before starting any project phase, conduct value-mapping sessions with key stakeholders and customers. Create specific, measurable definitions of value for your project. Document customer success criteria in their own words. Review every planned activity against these value definitions, eliminating or deferring anything that doesn’t directly contribute to customer-defined value.

2. Map the Value Stream

Once you’ve defined value, the second principle requires mapping the entire sequence of activities, the value stream, that transforms inputs into deliverables customers value. Value stream mapping visualizes every step in your project process, identifying which activities add value and which represent waste.

A comprehensive value stream map includes all activities, not just the obvious project tasks, but also approvals, handoffs, waiting periods, rework, reviews, and hidden work. It reveals the true flow of work through your organization, exposing bottlenecks, redundancies, and non-value-adding activities that consume time and resources.

The power of value stream mapping lies in its ability to reveal waste that’s become invisible through familiarity. Teams grow accustomed to lengthy approval processes, excessive documentation, unnecessary meetings, and waiting periods, accepting them as “just how things work.” Value stream mapping makes these inefficiencies visible and quantifiable, creating urgency for improvement.

Practical Application: Select a typical project or process in your organization. Map every single step from initial request through final delivery, including time required for each activity and waiting periods between steps. Categorize each activity as value-adding (customer would pay for it) or non-value-adding (necessary but customer wouldn’t pay) or waste (neither). Calculate the percentage of time spent on value-adding activities, most organizations discover it’s shockingly low, often below 20%.

3. Create Flow by Eliminating Obstacles

The third Lean principle focuses on creating smooth, uninterrupted flow of work through your value stream. Traditional project management often creates batch-and-queue processes, completing large batches of work before passing them to the next stage, where they wait in queues. This creates long cycle times, late feedback, and hidden problems.

Flow means work moves continuously through your process without interruptions, delays, or waiting periods. Like a river flowing smoothly rather than a series of pools and dams, efficient flow delivers value faster and reveals problems immediately. When work flows smoothly, issues surface quickly rather than hiding in queues or batches until much later.

Creating flow requires eliminating obstacles that interrupt work: unclear requirements, approval bottlenecks, resource constraints, technical dependencies, and handoff delays. It demands cross-functional collaboration, empowered teams, and systems that enable rapid decision-making rather than hierarchical approval processes.

Practical Application: Identify the biggest obstacles to flow in your projects. Common flow-killers include approval bottlenecks (work waiting for sign-offs), resource conflicts (shared resources working on too many projects simultaneously), unclear requirements (work stopping for clarification), and excessive handoffs (work passing through too many people or teams). Implement solutions like delegated decision authority, dedicated team members, and definition-of-ready checklists that prevent work from starting until properly prepared.

4. Establish Pull Based on Customer Demand

The fourth principle shifts from push-based to pull-based work systems. In push systems, work is scheduled and assigned based on plans, forecasts, or resource availability regardless of downstream capacity or customer readiness. This creates inventory (completed work waiting for the next step), overproduction (work done before needed), and misalignment with actual demand.

Pull systems start work only when downstream processes or customers are ready to receive it. Rather than producing according to schedules, teams respond to actual demand signals. This prevents overproduction, reduces inventory, and ensures work aligns with current priorities rather than outdated plans.

In project management, pull means starting tasks only when prerequisites are complete, resources are available, and downstream processes can accept the work. It prevents teams from starting too much work simultaneously, reducing work-in-progress and enabling focus on completing items before starting new ones.

Practical Application: Implement work-in-progress (WIP) limits for your team. Instead of allowing unlimited tasks “in progress,” establish maximum limits (e.g., no more than 2-3 tasks per person simultaneously). When someone completes work, they “pull” the next priority item rather than having new work “pushed” onto their plate. Use visual boards like Kanban to make work-in-progress visible and enforce WIP limits, preventing overload and enabling focus.

5. Pursue Continuous Improvement (Kaizen)

The fifth and final principle embeds continuous improvement, kaizen in Japanes, into organizational DNA. Lean recognizes that perfection is impossible, but improvement is always possible. Rather than accepting current performance as “good enough,” Lean organizations relentlessly seek incremental improvements in every process, every day.

Continuous improvement isn’t occasional; it’s systematic and ongoing. It empowers frontline teams to identify problems and experiment with solutions rather than waiting for management directives. It creates safe environments where problems are treated as opportunities for learning rather than occasions for blame. It celebrates small, incremental gains that compound over time rather than waiting for dramatic transformations.

Kaizen involves everyone in improvement, not just managers or quality teams, but every team member. It recognizes that people closest to the work often have the best insights into inefficiencies and practical solutions. It establishes regular cadences for reflection, learning, and experimentation.

Practical Application: Establish regular retrospectives or improvement sessions (weekly or bi-weekly) where teams reflect on what’s working well and what could improve. Use structured formats like Start-Stop-Continue or the 5 Whys to identify root causes. Implement small experiments to test improvement ideas, measuring results and adjusting approaches. Celebrate improvements publicly, reinforcing the value of continuous learning and adaptation.

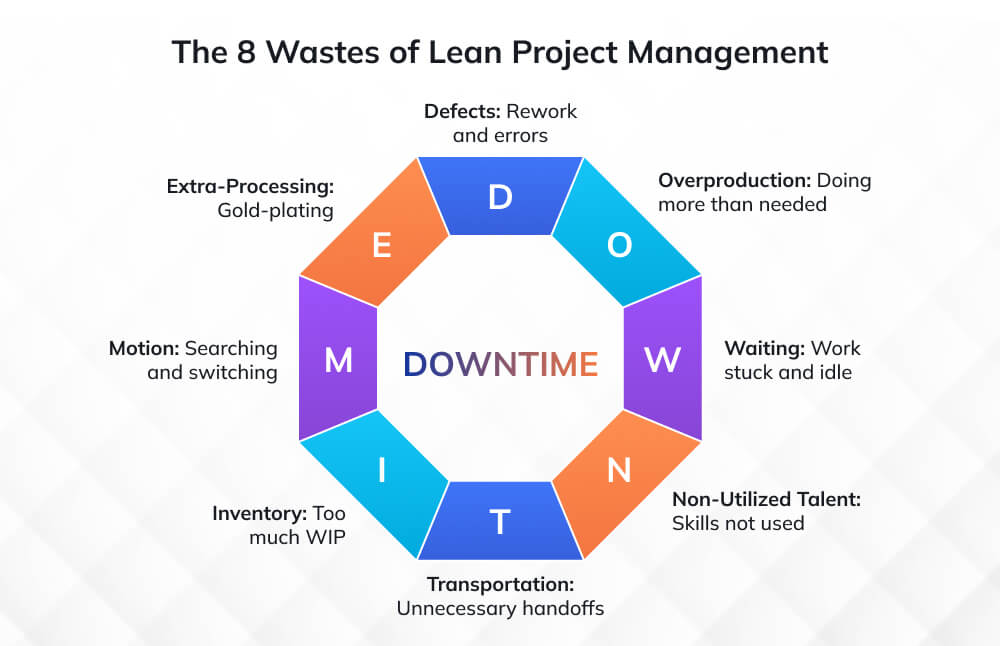

The Eight Types of Waste (Muda) in Project Management

Lean treats waste (muda) as anything that consumes time, money, or energy without creating value that the customer actually cares about. In projects, the classic eight wastes are a simple lens to find where your effort is leaking.

Below is a compressed overview of each waste type and how it shows up in project work.

- Defects and Rework

Errors, missed requirements, bugs, and incomplete deliverables that must be fixed later.

- Project examples: wrong reports, misinterpreted requirements, failed test cases.

- Countermeasures: clear Definition of Done, peer reviews, early validation with stakeholders, automated testing.

- Overproduction

Doing more than is needed, earlier than needed.

- Project examples: heavy documentation nobody reads, building “nice-to-have” features before core ones, over-detailed plans for uncertain future phases.

- Countermeasures: “just-in-time” planning, incremental delivery, ruthless pruning of non-essential outputs.

- Waiting and Delays

Work sits idle because it’s blocked by someone or something.

- Project examples: tasks waiting for approvals, clarifications, access, or shared resources.

- Countermeasures: delegated authority, clearer decision rules, Definition of Ready, breaking dependencies to enable more work to proceed in parallel.

- Non-Utilized Talent

Not using people’s skills, ideas, or judgment.

- Project examples: senior people doing low-value admin tasks, team members not involved in solving problems they understand best.

- Countermeasures: empower teams to decide within their domain, invite ideas from everyone, cross-train, and flatten decision-making where possible.

- Transportation

Unnecessary movement of work, information, or artifacts between people and systems.

- Project examples: excessive handoffs between teams, routing everything through a coordinator, and manually moving data across tools.

- Countermeasures: form cross-functional teams around value streams, integrate tools, reduce approval layers, and handoffs.

- Inventory (Work in Progress)

Partially done work that is started but not finished.

- Project examples: half-done requirements, code not yet tested, items “in progress” for multiple sprints.

- Countermeasures: strict WIP limits, “finish before starting” culture, smaller work items, and visual boards to expose stale tasks.

- Motion

Unnecessary effort to find, navigate, or re-create things.

- Project examples: hunting for the latest template, digging through email threads for decisions, bouncing between tools to piece together status.

- Countermeasures: single sources of truth, standard naming and folder structures, automation for repetitive tasks, and better tool configuration.

- Over-Processing (Extra-Processing)

Doing more work or using more complex solutions than needed to meet the requirement.

- Project examples: gold-plated features, over-engineered technical solutions, overly polished decks when a simple brief would do.

- Countermeasures: define “good enough” explicitly, use MVP thinking, challenge non-essential refinements.

The 8 Wastes of Lean Project Management (DOWNTIME)

| Waste Type | Description | Project Example | Impact | Elimination Tactic |

| Defects | Errors requiring rework | Bugs, requirement errors, incomplete deliverables | 10-100x cost increase if found late | Built-in quality, peer reviews, automated testing |

| Overproduction | Creating more than needed | Unused features, excessive documentation | Wasted effort, storage costs | Just-in-time delivery, incremental approach |

| Waiting | Idle time between activities | Approval delays, resource conflicts, dependencies | Extended cycle time, schedule delays | Delegated authority, parallel work, ready definitions |

| Non-utilized Talent | Underused skills and ideas | Limited decision authority, ignored expertise | Disengagement, missed innovation | Empowerment, cross-training, psychological safety |

| Transportation | Unnecessary movement | Excessive handoffs, information transfers | Communication loss, coordination overhead | Reduce handoffs, co-location, integrated tools |

| Inventory | Excess work-in-progress | Too many started tasks, incomplete items | Delayed feedback, extended cycle times | WIP limits, finish before starting, visual management |

| Motion | Unnecessary physical/mental effort | Searching for information, tool switching | Accumulated time loss, frustration | Information organization, single sources, automation |

| Extra-processing | Unnecessary work | Gold-plating, excessive detail, over-engineering | Delayed delivery, increased complexity | Define “good enough,” MVP approach, challenge features |

PRO TIP: Start With One Waste Type

Don’t try to eliminate all eight waste types simultaneously—it’s overwhelming and rarely effective. Instead, use your value stream map to identify which waste type causes the most delay or cost in your specific projects. Focus team efforts on systematically eliminating that one waste type for 2-3 months. Once you’ve made significant progress and established new habits, tackle the second most impactful waste type. This focused approach generates visible improvements that build momentum for broader Lean adoption.

Practical Application: Implementing Lean in Your Projects

Understanding Lean principles and waste types provides the foundation, but real value comes from practical application. Lean implementation doesn’t require massive transformation initiatives; it starts with small, focused changes that compound over time.

Getting Started with Lean Project Management

Begin by selecting a single project or process as your Lean pilot. Choose something important but not mission-critical, significant enough that improvements matter, but low-risk enough that experimentation is safe. Assemble a small team genuinely committed to trying new approaches.

Conduct a value stream mapping session with your team. Map your current process from start to finish, including every activity, decision point, handoff, and waiting period. Calculate the percentage of time spent on value-adding versus non-value-adding activities. Most teams find that less than 20% of their time creates actual customer value, a sobering yet motivating realization.

Use the DOWNTIME mnemonic to identify which waste types most significantly plague your process. Calculate the cost of these wastes in time, money, and opportunity. Present findings to stakeholders, making the business case for improvement.

Lean Tools and Techniques for Project Teams

- Kanban Boards: Visualize work flowing through your process using physical or digital Kanban boards. Create columns for each process stage (e.g., Backlog, Ready, In Progress, Review, Done). Represent work items as cards moving through columns. Implement WIP limits that prevent overload. Kanban makes work visible, reveals bottlenecks, and enforces focus on finishing before starting.

- Daily Stand-Ups: Brief daily team synchronizations (15 minutes maximum) where members share progress, upcoming work, and obstacles. Stand-ups promote alignment, identify blockers quickly, and create accountability. They replace lengthy status meetings with efficient daily touchpoints.

- Retrospective: Regular team reflection sessions (weekly or bi-weekly) focused on continuous improvement. Use structured formats (Start-Stop-Continue, 4Ls, Sailboat) to identify what’s working and what needs improvement. Generate actionable experiments to test improvement ideas. Track results and adjust approaches.

- 5 Whys Root Cause Analysis: When problems occur, ask “why” five times to reach root causes rather than treating symptoms. Example: “Why did the deployment fail?” → “Because testing was incomplete” → “Why?” → “Because we rushed testing to meet deadlines” → “Why?” → “Because requirements changed late in the cycle” → “Why?” → “Because we didn’t involve stakeholders early” → “Why?” → “Because we lack a regular stakeholder review cadence.” Solution: Implement weekly stakeholder demos.

- A3 Problem Solving: One-page structured problem-solving format named after A3 paper size. Includes problem statement, current state analysis, root cause investigation, target state definition, solution proposals, implementation plan, and follow-up. A3 thinking forces clarity, conciseness, and systematic analysis.

Lean Across Industries Beyond Manufacturing

While Lean originated in manufacturing, its principles apply universally wherever work occurs. Software development teams apply Lean principles through practices such as continuous integration, automated testing, and iterative development. Healthcare organizations apply Lean to reduce patient waiting times, eliminate medical errors, and improve care coordination. Financial services firms leverage Lean to streamline loan processing, reduce compliance overhead, and accelerate service delivery.

Construction projects implement Lean through the Last Planner System, pull scheduling, and on-site waste reduction. Marketing teams apply Lean to campaign development, reducing approval cycles and enabling rapid experimentation. Even government agencies adopt Lean principles to improve citizen services, reduce bureaucratic delays, and maximize taxpayer value.

The common thread: regardless of industry or domain, Lean provides frameworks for identifying value, eliminating waste, and continuously improving how work gets done.

| AVOID THIS MISTAKE: Lean as a One-Time Event

Don’t treat Lean implementation as a one-time project with a finish date. Organizations often launch “Lean initiatives,” implement some tools, declare success, then revert to old habits when attention shifts elsewhere. Lean isn’t a project; it’s a management philosophy and a cultural transformation that require ongoing commitment. Why it’s problematic: Without sustained commitment, initial improvements erode. Teams revert to comfortable old patterns when facing pressure. Lean becomes viewed as another “flavor of the month” management fad, creating cynicism that undermines future improvement efforts. What to do instead: Treat Lean as a journey, not a destination. Embed Lean thinking into daily management routines, regular gemba walks (going to where work happens), ongoing problem-solving, and continuous experimentation. Celebrate improvements, but always ask “what could be even better?” Make kaizen a permanent organizational value, not a temporary initiative. |

Conclusion

In 2026, Lean Project Management is no longer a niche philosophy; it’s a practical way to survive aggressive timelines, rising costs, and unforgiving customer expectations. Teams that truly apply Lean thinking deliver faster, with fewer defects, less chaos, and far more clarity on what actually creates value for the customer.

The core advantage is simple: you stop paying for waste. By clearly defining value, mapping value streams, reducing work-in-progress, and relentlessly eliminating the eight wastes, you shorten cycle times, lower project risk, and create space for continuous improvement rather than constant firefighting. Lean also strengthens culture: teams feel more in control of their work, leadership gains greater visibility, and stakeholders see tangible improvements rather than slide decks.

You don’t need a massive transformation program to start. Pick one project, expose the value stream, choose one waste type to eliminate, and run one small improvement experiment. Then repeat. Lean works through disciplined repetition, not grand one-time initiatives.

If you want a structured way to deepen your skills and turn these ideas into consistent practice, explore Invensis Learning’s Lean Project Management Training Course. It’s designed to help you apply Lean principles, tools, and waste-elimination techniques directly to real projects, enabling you to move from theory to measurable results.

Frequently Asked Questions

1. What is the difference between Lean and Agile project management?

Lean and Agile share common principles but have different origins and emphasis. Lean originated in manufacturing (Toyota Production System) focused on waste elimination and continuous flow. Agile emerged from software development, emphasizing iterative delivery and customer collaboration. In practice, they complement each other, many Agile practices (Kanban, continuous improvement, customer focus) derive from Lean principles. Lean provides the philosophical foundation and waste-elimination focus, while Agile offers specific practices for iterative delivery. Modern project management often combines both, using Lean thinking to identify waste and Agile practices to deliver value iteratively.

2. Can Lean principles apply to creative or knowledge work, or only to manufacturing?

Absolutely, Lean principles apply universally to any type of work. While Lean’s language and examples often reference manufacturing, the underlying principles (defining value, eliminating waste, creating flow, continuous improvement) transcend industry boundaries. Software teams use Lean through practices like continuous integration and DevOps. Marketing teams apply Lean to campaign development. Healthcare uses Lean to improve patient care. Government agencies leverage Lean for citizen services. The key is translating manufacturing terminology into your context—“inventory” becomes work-in-progress, “defects” become rework or errors, and “value stream” represents your workflow from request to delivery.

3. How long does it take to implement Lean project management successfully?

Lean implementation isn’t an event with a completion date, it’s an ongoing journey of continuous improvement. That said, initial results often emerge quickly. Teams typically see measurable improvements in cycle time, quality, or efficiency within 2-3 months of focused effort on a pilot project. However, cultural transformation, where Lean thinking becomes “how we work” rather than something extra we do, requires 18-36 months of sustained commitment. Start expecting quick wins from initial waste elimination while building toward long-term cultural change. Focus on progress, not perfection, celebrating improvements while continuously seeking further enhancement.

4. What are common obstacles to Lean implementation and how can they be overcome?

The most common obstacles include:

- Resistance to change: Overcome through education, involving resisters in improvement experiments, and demonstrating early wins.

- Lack of leadership commitment: Address by presenting business cases showing waste costs, sharing success stories, and starting with supportive leaders.

- Insufficient training: Provide comprehensive Lean education, not just tool training, emphasizing principles and thinking.

- Treating Lean as a program rather than philosophy: Embed Lean into daily management practices, ongoing routines, and organizational values.

- Attempting too much too fast: Start with focused pilots, build capability gradually, and expand based on demonstrated success rather than ambitious timelines.

5. Do I need certification to practice Lean project management?

Certification isn’t required to practice Lean principles or implement waste elimination in your projects. Many successful Lean practitioners learn through books, practice, and mentorship without formal certification. However, Lean Six Sigma certifications (Yellow Belt through Black Belt) provide structured learning paths, validate your knowledge, enhance credibility with employers and clients, and demonstrate commitment to excellence. Certifications are particularly valuable if you’re seeking roles specifically requiring Lean expertise, want to lead organizational transformation initiatives, or need credible validation of your skills. Ultimately, practical application matters more than credentials, certification validates knowledge, but real-world results demonstrate capability.

6. How does Lean integrate with other project management methodologies like PMP or PRINCE2?

Lean complements traditional project management frameworks rather than replacing them. PMP and PRINCE2 provide comprehensive frameworks for project governance, planning, and control. Lean adds specific focus on waste elimination, value creation, and continuous improvement within those frameworks. Many certified PMPs incorporate Lean principles into their PMP practice, using value stream mapping during project planning, implementing Kanban for task management, or conducting kaizen events to improve processes. The combination is powerful: traditional PM frameworks provide structure and governance while Lean principles optimize efficiency and value delivery within that structure. Modern hybrid approaches blend the best elements of multiple methodologies.