Now, the global logistics market has reached $12.4 trillion, with over 68% of supply chain executives reporting that managing complex logistics projects has become their top operational challenge. As supply chains grow increasingly interconnected and customer expectations for speed and transparency continue to rise, the need for structured project management in logistics has never been more critical.

Traditional logistics operations management focuses on day-to-day activities, moving goods, managing inventory, and coordinating shipments. But what happens when you need to implement a new warehouse management system, redesign your distribution network, or integrate sustainability initiatives across your supply chain? These are projects, not operations, and they require a fundamentally different management approach.

This comprehensive guide will walk you through the essential frameworks, methodologies, tools, and best practices for successfully managing logistics projects. Whether you’re implementing new technology, optimizing transportation routes, or building distribution infrastructure, you’ll discover how to plan, execute, and deliver projects that transform your supply chain operations.

Table of Contents:

- Understanding Project Management in the Logistics Context

- Core Components of Logistics Project Management

- Project Management Methodologies for Logistics

- Essential Tools and Technologies for Logistics Project Management

- Best Practices for Successful Logistics Project Management

- Skills and Certifications for Logistics Project Managers

- Future Trends in Logistics Project Management

- Conclusion

- Frequently Asked Questions

Understanding Project Management in the Logistics Context

What is Logistics Project Management?

Logistics project management is the disciplined application of project management principles, methodologies, and tools to temporary endeavors within the supply chain and logistics domain. Unlike ongoing logistics operations that focus on maintaining steady-state activities, logistics projects have defined beginnings and ends, specific objectives, and deliver unique outcomes, such as a new distribution center, an optimized route network, or an implemented technology platform.

The scope encompasses everything from warehouse automation initiatives and transportation network redesigns to last-mile delivery innovations and supply chain sustainability programs. Each project must balance the traditional triple constraint of scope, time, and cost while navigating the unique complexities of logistics environments.

Why Traditional Project Management Isn’t Enough for Logistics

Logistics projects operate in uniquely complex environments that demand specialized approaches:

- Real-time operational dependencies: Unlike software development or construction projects, logistics projects often run parallel to ongoing operations that cannot stop. A warehouse management system implementation must account for continuous order fulfillment, and a distribution network redesign cannot halt daily deliveries.

- Multi-stakeholder ecosystems: Logistics projects typically involve numerous external parties, carriers, suppliers, customers, regulatory bodies, and technology vendors, each with different priorities, systems, and constraints. This creates coordination challenges far exceeding typical internal projects.

- Dynamic external factors: Weather disruptions, fuel price fluctuations, regulatory changes, and geopolitical events can impact logistics projects mid-execution in ways that require immediate adaptation rather than formal change control processes.

| PRO TIP

Not everything in logistics is a project. Daily route planning, regular inventory replenishment, and standard shipment processing are operations. Projects have clear start and end dates and create something new or different—like implementing route optimization software (project) versus using that software daily (operations). Confusing the two leads to either over-engineering simple tasks or under-planning complex initiatives. |

Core Components of Logistics Project Management

Project Initiation and Stakeholder Mapping

Every successful logistics project begins with thorough stakeholder identification and engagement planning. In logistics, stakeholders extend far beyond your internal team to include carriers, warehouse operators, customs brokers, technology vendors, and critically, the operational teams whose daily work will be impacted.

Start by creating a comprehensive stakeholder map that categorizes parties by their level of influence and interest. High influence, high-interest stakeholders, such as your VP of Operations or your primary carrier partner, require active management and frequent communication. High influence, low-interest parties, perhaps your CFO or IT security team, need enough engagement to maintain their support without overwhelming them with operational details.

For example, when a Fortune 500 retailer implemented automated guided vehicles (AGVs) in their distribution center, their stakeholder map included 47 distinct parties: warehouse associates who would work alongside the robots, union representatives, safety compliance officers, the AGV vendor’s technical team, facility maintenance staff, IT network engineers, and even the local fire department who needed to understand emergency shutdown procedures.

Develop a stakeholder engagement matrix that specifies communication frequency, preferred channels, and key information needs for each group. Your warehouse operations manager might need daily progress updates via team huddles, while your executive sponsor prefers weekly dashboard reviews and monthly steering committee presentations.

Planning and Resource Allocation

Logistics project planning requires balancing multiple resource types: human capital, physical assets, technology infrastructure, and financial budgets. Unlike purely digital projects, logistics initiatives often involve tangible resources that cannot be scaled or reassigned at will.

Resource identification starts with a detailed work breakdown structure (WBS) that decomposes your project into manageable components. For a transportation management system (TMS) implementation, your WBS might include modules for: vendor selection, data migration, system configuration, carrier integration, user training, pilot testing, and full rollout.

Critical path analysis is particularly important in logistics, given long equipment procurement lead times and the sequential nature of many activities. When planning a new distribution center, you cannot begin installing racking systems until the building shell is complete, and you cannot train staff on equipment that hasn’t been installed. Identifying these dependencies early prevents costly delays.

Budget planning must account for both direct project costs and the often-overlooked operational impact costs. A warehouse automation project might have a $2 million capital budget, but what about the productivity dip during training, the temporary labor needed to maintain service levels during transition, or the expedited shipping costs if the cutover takes longer than planned?

Risk identification should be exhaustive and logistics-specific. Common risk categories include: technology integration failures, vendor delivery delays, labor resistance to change, seasonal demand spikes during implementation, and regulatory compliance issues. For each identified risk, develop both mitigation strategies (reducing likelihood) and contingency plans (reducing impact if it occurs).

Execution and Coordination

The execution phase is where logistics project management diverges most dramatically from traditional project management. You’re not just coordinating tasks; you’re orchestrating change within a live, operating supply chain that serves customers in real-time.

Cross-functional team management in logistics demands bringing together diverse expertise: supply chain analysts, warehouse supervisors, IT developers, carrier relationship managers, and frontline operational staff. Each group speaks a different language and operates on different timelines. Your analysts think in quarterly planning cycles, your IT team in two-week sprints, and your warehouse supervisors in daily shifts.

Establish communication protocols that bridge these different operational rhythms. Daily standups work well for active implementation phases, but don’t drag your executive sponsor into daily tactical discussions. Create tiered communication structures: daily tactical coordination for core team members, weekly progress reviews for functional leaders, and monthly steering committees for executives and key stakeholders.

Technology integration represents one of the most challenging execution elements. Most logistics projects involve connecting new systems to existing warehouse management systems (WMS), transportation management systems (TMS), enterprise resource planning (ERP) platforms, and carrier electronic data interchange (EDI) connections. Each integration point is a potential failure point requiring careful testing and validation.

Real-time monitoring systems should track both project progress metrics (tasks completed, budget consumed, timeline adherence) and operational performance metrics (order accuracy, on-time shipments, labor productivity) to ensure your project isn’t inadvertently degrading service quality.

Monitoring, Control, and Optimization

Effective logistics project control requires establishing clear key performance indicators (KPIs) that measure both project health and operational impact. Project health KPIs include schedule variance, cost variance, scope change frequency, and risk occurrence rates. Operational impact KPIs monitor whether your project is maintaining or improving metrics like order fulfillment accuracy, on-time delivery percentages, inventory accuracy, and labor productivity.

Develop performance dashboards that provide at-a-glance visibility for different stakeholder groups. Your project team needs detailed task-level tracking, your operations managers need to see service level impacts, and your executives need high-level status indicators with exception-based alerts.

Establish corrective action triggers, predefined thresholds that automatically escalate issues. If your project falls more than one week behind schedule, trigger a recovery plan review. If operational accuracy drops below 95% during implementation, pause deployment and diagnose the issue before proceeding.

Build continuous improvement loops into your project by conducting regular retrospectives. Don’t wait until project completion to capture lessons learned. Hold mini-retrospectives at major milestone completions to identify what’s working, what isn’t, and what adjustments should be made for upcoming phases.

Project Management Methodologies for Logistics

Waterfall Methodology in Logistics Projects

The traditional waterfall approach, where projects progress sequentially through defined phases of initiation, planning, execution, monitoring, and closure, remains highly effective for specific types of logistics projects, particularly those involving physical infrastructure or complex regulatory compliance.

Infrastructure projects are natural candidates for waterfall methodology. When constructing a new distribution center, you cannot begin installing conveyor systems before the building foundation is complete, and you cannot train staff on equipment that hasn’t been installed. The sequential dependencies are real and immutable, making waterfall’s phase-gate approach appropriate.

Consider the case of a national retailer building a 1.2-million-square-foot automated distribution center in Texas. The project followed classic waterfall methodology: site selection and permitting (3 months), design and engineering (4 months), construction (18 months), equipment installation (6 months), testing and commissioning (3 months), and staff training and ramp-up (2 months). Each phase had clear deliverables and approval gates before proceeding to the next phase.

Advantages of waterfall in logistics include: clear documentation and audit trails (critical for regulatory compliance), well-defined budgets and timelines (important for capital projects requiring board approval), and reduced complexity in managing stakeholder expectations (everyone knows the plan upfront).

Limitations become apparent when requirements change mid-project or when operational learning from early phases should inform later decisions. A warehouse layout designed in month 4 might prove suboptimal when actual equipment is installed in month 24, but the waterfall’s rigid structure makes mid-course corrections difficult and expensive.

Agile and Scrum for Logistics Projects

Agile methodologies, originally developed for software development, have proven highly applicable to logistics projects involving technology implementation, process optimization, and customer experience enhancement. The core principles of iterative development, frequent feedback, and adaptive planning align well with logistics’ need for operational flexibility.

Sprint planning for logistics typically uses two- to four-week sprints rather than software’s traditional two-week cycles, acknowledging that logistics changes often require longer validation periods to assess operational impact. Each sprint delivers working functionality that can be tested in real operational conditions.

A European logistics provider used Scrum methodology to optimize their last-mile delivery operations across 12 cities. Rather than designing a comprehensive solution upfront, they treated each city as a two-week sprint. The first sprint in Amsterdam focused on route optimization algorithms. The second sprint in Rotterdam added dynamic customer delivery windows. The third sprint in The Hague incorporated real-time traffic data. Each sprint built on learnings from previous iterations, and underperforming features could be quickly adjusted or abandoned.

Scrum ceremonies adapted for logistics include:

- Daily standups: 15-minute check-ins focused on blockers and dependencies

- Sprint planning: Operational teams collaborate with project teams to define feasible sprint goals

- Sprint reviews: Demonstrations of working functionality in actual operational environments

- Retrospectives: Team reflections on what worked, what didn’t, and what to adjust

The product backlog in logistics Scrum includes not just technical features but operational enhancements: “Reduce average picking time by 15 seconds per order,” “Increase truck utilization from 83% to 87%,” or “Enable customers to modify delivery addresses up to 2 hours before arrival.”

Critical success factors for Agile in logistics include: maintaining operational stability during iterations (changes must not disrupt customer service), securing buy-in from frontline operational staff (they’re your end users and testers), and accepting that not everything can be agile (some infrastructure investments require upfront commitments).

Hybrid and Adaptive Approaches

Most complex logistics projects benefit from hybrid methodologies that combine waterfall’s structured planning for infrastructure components with Agile’s iterative approach for technology and process elements.

A transportation management system (TMS) implementation might use waterfall methodology for the infrastructure phases, server procurement, network configuration, and database setup, where requirements are fixed and sequential. Then switch to Agile sprints for the configuration and user experience optimization phases, where operational feedback should shape the solution.

PRINCE2 in logistics offers a middle ground, with a focus on business case justification, defined organizational structures, and product-based planning. PRINCE2’s emphasis on exception management aligns well with logistics operations, where most processes run smoothly but require rapid escalation when problems occur.

Lean Six Sigma integration brings powerful tools for process improvement within logistics projects. DMAIC (Define, Measure, Analyze, Improve, Control) provides a structured framework for identifying root causes of operational inefficiencies and validating that project solutions actually deliver measurable improvements.

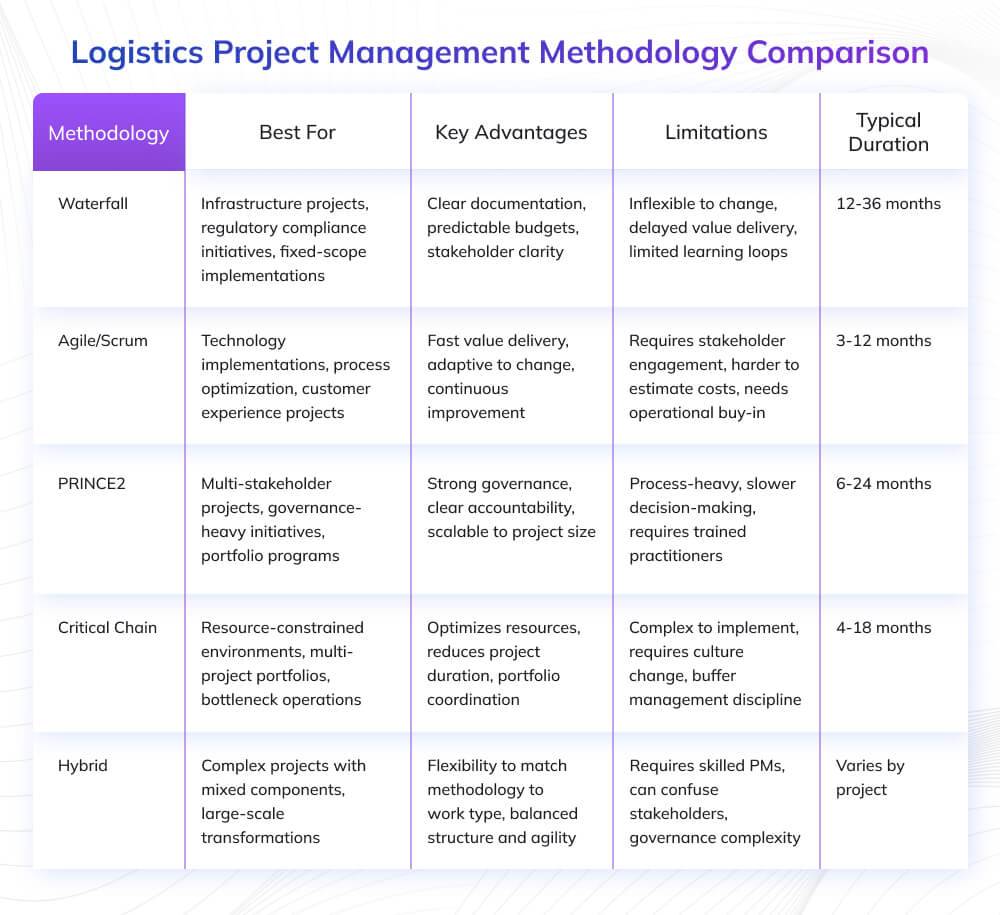

The methodology selection framework should consider:

- Requirement stability: Fixed requirements favor waterfall; evolving requirements favor Agile

- Physical dependencies: Infrastructure projects with hard sequential dependencies need waterfall elements

- Regulatory constraints: Compliance-heavy projects often require waterfall’s documentation rigor

- Stakeholder complexity: Projects with numerous external parties may need PRINCE2’s governance structure

- Innovation level: Exploratory or innovative projects benefit from Agile’s iterative learning

Critical Chain Project Management for Logistics

Critical Chain Project Management (CCPM) deserves special consideration in logistics due to the resource-constrained nature of most supply chain operations. Unlike traditional critical path analysis that focuses on task dependencies, CCPM focuses on resource dependencies and bottlenecks.

In logistics, resources are almost always constrained: you have limited warehouse space for staging during implementations, limited technical staff who can configure systems, limited time windows when operations can be disrupted for testing, and limited capacity on your network to migrate data without impacting transaction performance.

CCPM addresses these constraints through buffer management. Instead of padding each individual task with contingency time (which research shows gets wasted through Parkinson’s Law—work expands to fill available time), CCPM concentrates buffers at strategic points: project completion buffers, feeding buffers where non-critical chains join the critical chain, and resource buffers that ensure constrained resources are available when needed.

This approach proves particularly valuable in multi-project environments common in large logistics operations where the same warehouse managers, systems architects, and integration specialists support multiple concurrent initiatives. CCPM helps sequence projects and allocate shared resources to maximize overall portfolio throughput rather than optimizing individual project timelines.

Key Challenges in Logistics Project Management

Managing Global Supply Chain Disruptions

Logistics projects operate in environments characterized by constant disruption. Port congestion, weather events, geopolitical tensions, and capacity constraints can derail even the most carefully planned implementations. Disruption resilience must be built into project plans from the outset.

Develop scenario plans for likely disruption types. If your project depends on equipment manufactured in Asia, what happens if shipping delays extend lead times by 8 weeks? If you’re implementing technology that requires on-site vendor support, how will you proceed if travel restrictions prevent their arrival? These aren’t edge cases, they’re probable events requiring predetermined responses.

Mitigation strategies include: maintaining longer planning horizons for critical path items, diversifying vendor and supplier dependencies, building flexibility into contracts (include force majeure provisions but also define specific remediation steps), and establishing expedited decision-making protocols for crisis situations.

Technology Integration Complexity

Legacy system challenges plague most logistics projects. Your new warehouse management system must integrate with a 15-year-old ERP system; your transportation optimization tool must exchange data with carrier systems using outdated EDI standards; and your real-time visibility platform must aggregate data from dozens of disparate sources.

Technical integration challenges are often solvable; middleware platforms, API layers, and data transformation tools provide connectivity. The harder challenge is data quality and standardization. When combining systems that use different product codes, location identifiers, and measurement units, someone must build the master data management frameworks and translation tables, tedious work that project teams often underestimate.

Change management issues emerge when new systems alter established workflows. Warehouse associates who’ve picked orders the same way for a decade must suddenly follow different procedures. Dispatchers accustomed to manual route planning must trust algorithmic recommendations. Resistance isn’t irrational; it’s a natural response to disrupted mastery and increased cognitive load during learning periods.

Stakeholder Alignment and Communication

Multi-party coordination becomes exponentially more complex as the number of stakeholders increases. A simple warehouse management system implementation might involve: your internal IT team, the WMS vendor’s implementation team, your network infrastructure provider, your barcode label supplier, your material handling equipment vendor whose controls must integrate, your third-party logistics provider if you use contract warehousing, and your largest customers who may have specific data exchange requirements.

Each party has different priorities, timelines, and communication preferences. Your vendor wants to deploy quickly to recognize revenue and move to the next client. Your IT team wants thorough testing and security validation. Your operations team wants minimal disruption during peak season. Your finance team wants to stay within budget.

Conflict resolution requires balancing competing interests through transparent trade-off discussions. If the vendor wants to cut the integration testing phase by two weeks, what additional risk does that create, and who bears that risk? Make trade-offs explicit and ensure decision rights are clearly defined in your project governance structure.

Budget and Time Constraints

Common overrun causes in logistics projects include: scope creep from stakeholders requesting “just one more feature,” underestimated integration complexity, vendor delivery delays, and the hidden cost of maintaining operational performance during implementation (often requiring temporary labor or work-arounds).

Prevention tactics center on rigorous change control, realistic initial estimation (including lessons learned from prior projects), explicit scope boundaries (say no early and often), and separate budget contingency reserves for known unknowns (integration debugging) versus unknown unknowns (major external disruptions).

| AVOID THIS MISTAKE:

Assuming technology vendor timeline estimates are realistic for your environment Why it’s problematic: Vendors quote implementation timelines based on ideal conditions with committed full-time resources, clean data, and decisive stakeholders. Real logistics environments have messy data, part-time resources juggling operations and projects, and consensus-based decision-making that slows progress. What to do instead: Add 40-60% to vendor timeline estimates for internal tasks (data cleansing, testing, training). Build explicit time buffers for integration debugging. Create detailed work plans that account for your actual resource availability, not theoretical full-time allocation. Placement Context: After technology integration subsection to warn about common estimation pitfalls |

Essential Tools and Technologies for Logistics Project Management

Project Management Software Platforms

Enterprise solutions like Microsoft Project, Oracle Primavera, and SAP Portfolio Management provide comprehensive project planning, resource management, and portfolio oversight capabilities. These platforms excel in managing large-scale, complex logistics programs with multiple workstreams, hundreds of tasks, and intricate dependencies.

Microsoft Project integrates seamlessly with Microsoft 365 ecosystems common in corporate environments, enabling resource scheduling aligned with Outlook calendars and document management via SharePoint. Primavera’s strengths lie in critical path analysis and resource leveling for massive infrastructure projects, ideal for distribution center construction or network redesign initiatives involving thousands of interrelated activities.

Cloud-based platforms including Asana, Monday.com, Smartsheet, and Wrike offer more accessible, collaborative alternatives particularly well-suited for cross-functional logistics teams. These tools prioritize user experience and real-time collaboration over comprehensive project controls, making them ideal for technology implementation projects or process improvement initiatives where stakeholder engagement matters more than sophisticated scheduling algorithms.

Smartsheet’s spreadsheet-familiar interface reduces the learning curve for operations managers accustomed to Excel-based planning. Monday.com’s visual boards and automation capabilities help bridge communication gaps between technical and operational teams. Asana’s mobile-first design supports field-based project activities like warehouse assessments or carrier facility evaluations.

Selection criteria should emphasize: integration capabilities with your existing logistics systems (WMS, TMS, ERP), resource management functionality aligned with your needs (simple task assignment vs. complex capacity planning), reporting and dashboard capabilities that serve diverse stakeholder groups, and total cost of ownership including licensing, training, and administration.

Supply Chain Management Systems Integration

Transportation Management Systems (TMS) like Oracle Transportation Management, SAP Transportation Management, and MercuryGate provide the operational backbone for logistics projects involving carrier management, route optimization, or freight cost reduction. Projects often involve configuring these systems or integrating them with new components.

Warehouse Management Systems (WMS) including Manhattan Associates, Blue Yonder (formerly JDA), and SAP Extended Warehouse Management orchestrate warehouse operations. Implementation projects must carefully manage the cutover from legacy systems while maintaining operational continuity, you cannot simply turn off the old system on Friday and turn on the new system on Monday.

Integration architecture matters tremendously. Modern APIs and cloud-based integration platforms like MuleSoft, Dell Boomi, or TIBCO enable real-time data exchange between project management platforms and operational systems. This connectivity allows project teams to monitor whether implementations are improving operational metrics in real-time rather than waiting for weekly reports.

Real-time data sharing between project tools and operational systems provides powerful feedback loops. If your warehouse automation project aims to improve picking productivity by 20%, integrating your WMS productivity dashboards into your project monitoring system immediately shows whether you’re meeting that goal or need to adjust.

Collaboration and Communication Tools

Team collaboration platforms like Microsoft Teams, Slack, and Zoom have become essential infrastructure for logistics projects involving distributed teams, remote vendor support, and field-based operational staff.

Microsoft Teams’ integration with the broader Microsoft ecosystem creates unified workspaces where project documents, task lists, chat conversations, and video meetings coexist. Slack’s channel-based communication model helps organize conversations by topic (create channels for #warehouse-automation, #carrier-integration, #training-materials), preventing the notification overload that plagues email-based project communication.

Document management in SharePoint, Google Workspace, or specialized systems such as Box ensures version control, access permissions, and audit trails for project artifacts. In regulated industries or projects involving financial controls, document management systems that track who accessed which version of requirements documents or approval forms provide essential compliance evidence.

Analytics and Reporting Tools

Business intelligence platforms, including Tableau, Power BI, and Qlik, enable logistics project teams to create custom dashboards that combine project health metrics with operational performance indicators. These visualizations help executives quickly understand whether projects are on track and delivering intended value.

Power BI’s integration with Microsoft ecosystems and relatively low cost make it accessible for mid-sized logistics operations. Tableau’s superior visualization capabilities and data handling performance suit large-scale programs generating massive datasets. Qlik’s associative data model excels at ad-hoc analysis when project teams need to explore unexpected patterns.

Predictive analytics leveraging machine learning can forecast project risks before they materialize. Algorithms analyzing past project data can predict which types of tasks are likely to overrun, which stakeholder groups typically create bottlenecks, and which vendor dependencies introduce the most schedule risk.

Performance tracking systems should measure both leading indicators (activities completed, resources deployed, risks identified) and lagging indicators (milestones achieved, budget consumed, operational metrics improved). Leading indicators help you steer the project; lagging indicators tell you whether you reached your destination.

Best Practices for Successful Logistics Project Management

Establish Clear Communication Channels

Create a communication matrix that specifies who needs what information, how frequently, through which channels, and in what format. Your executive sponsor doesn’t need daily task updates; they need weekly executive summaries with red/yellow/green status indicators and exception escalations. Your warehouse managers need daily operational impact reports showing whether today’s work affected order processing rates.

Communication frequency and format guidelines:

- Daily: Core project team standups (15 minutes, blockers only), operational impact alerts (automated from integrated systems)

- Weekly: Functional leader reviews (30 minutes, progress and upcoming risks), stakeholder newsletters (visual, scannable)

- Biweekly: Steering committee meetings (60 minutes, decisions required), vendor coordination calls

- Monthly: Executive sponsor briefings (30 minutes, strategic decisions), all-hands communications (celebrating wins, addressing concerns)

Build Flexibility into Project Plans

Buffer strategies should distinguish between different types of uncertainty. Use feeding buffers (time buffers before critical dependencies) to protect against routine variability in task completion. Use project buffers (time buffers before final deadlines) to absorb cumulative uncertainty. Use resource buffers (advance notifications) to ensure constrained resources are available when needed.

Scenario planning prepares teams for probable disruptions. Develop specific playbooks for likely scenarios: “If our equipment vendor misses delivery by 4+ weeks, we will…” or “If operational testing reveals accuracy below 98%, we will…” Pre-approved response plans enable rapid adaptation without escalating every decision to steering committees.

Leverage Data for Decision-Making

Real-time dashboards should present role-appropriate information. Project managers need task-level detail with bottleneck identification. Operations managers need operational metrics that show the impact of implementation. Executives need high-level status with predictive forecasts (based on current trajectory, will we hit our deadline?).

Predictive analytics can identify risk patterns. If past projects show that tasks estimated between 40-60 hours typically run over by 30%, adjust your plans accordingly. If vendor X historically delivers 2 weeks late, build that into your schedule baseline rather than hoping this time will be different.

| PRO TIP

Build “learning sprints” into your project timeline, short periods explicitly dedicated to validating assumptions with real operational data before committing to full deployment. After configuring your warehouse management system but before training 200 associates, run a 3-day learning sprint with 5 experienced workers who will perform actual order fulfillment. The operational insights from this small investment prevent costly rework and change orders later. |

Focus on Stakeholder Engagement

Regular check-ins prevent surprises and build trust. Operations managers who feel informed and heard become project advocates. Operations managers who feel excluded and surprised become obstacles. Create formal touchpoints while maintaining informal communication channels; sometimes, the most valuable feedback comes from casual conversations.

Transparency practices mean sharing not just successes but also challenges and trade-offs. When you’re behind schedule, explain why, what you’re doing about it, and what help you need from stakeholders. Most stakeholders can handle bad news; they cannot handle surprises or feeling deceived.

Implement Continuous Improvement Processes

Post-project reviews capture lessons learned, but don’t wait until the project is complete. Hold mini-retrospectives at major milestone completions: “What have we learned so far? What should we keep doing? What should we change for the next phase?”

Lessons learned documentation should be actionable and specific, not generic platitudes. “Start requirements gathering earlier” is too vague. “Schedule requirements workshops with operational staff 3 months before vendor engagement rather than 1 month, this reduces scope changes during implementation by 40% based on the last two projects” is actionable guidance for future projects.

Create a project knowledge repository that preserves project artifacts, lessons learned, vendor assessments, and implementation guides for future teams. Too many logistics organizations repeatedly learn the same lessons because knowledge lives in individuals’ heads rather than accessible systems.

Skills and Certifications for Logistics Project Managers

Core Competencies Required

- Leadership and team management: Logistics project managers must inspire and coordinate diverse teams, including warehouse supervisors (focused on daily operations), IT developers (focused on code quality), executives (focused on ROI), and frontline workers (focused on workload and job security). Each group requires different motivation and communication approaches.

- Analytical and problem-solving skills: Complex logistics projects present ongoing challenges, integration issues, performance bottlenecks, stakeholder conflicts, and scope ambiguities. Strong analytical skills help diagnose root causes rather than treating symptoms, and systems thinking helps anticipate how changes in one area cascade throughout the supply chain.

- Technical logistics knowledge: You need sufficient domain expertise to understand warehouse operations, transportation planning, inventory management, and supply chain workflows. You don’t need to be a warehouse manager or transportation analyst, but you must speak their language and understand their constraints.

- Change management expertise: Logistics projects fail more often due to people issues than technical issues. Skilled change management, understanding sources of resistance, building coalitions, communicating benefits, and providing adequate training and support, sets successful implementations apart from failed deployments of perfectly good technology.

Relevant Project Management Certifications

PMP® (Project Management Professional): The gold standard project management certification from PMI validates comprehensive project management knowledge across initiation, planning, execution, monitoring, and closing. PMP certification requires 35 hours of project management education and passing a rigorous 180-question exam covering predictive, agile, and hybrid approaches.

For logistics professionals, PMP provides frameworks for managing complex, multi-stakeholder projects while demonstrating professional credibility to executives and external partners. The certification’s emphasis on stakeholder, risk, and integration management directly addresses logistics project challenges.

PRINCE2®: This structured project management methodology from AXELOS provides comprehensive governance frameworks, particularly valuable for logistics projects involving multiple organizations or regulatory oversight. PRINCE2’s principle-based approach (continued business justification, learn from experience, defined roles and responsibilities) aligns well with logistics operations’ focus on value delivery and accountability.

PMI-ACP® (Agile Certified Practitioner): For logistics professionals managing technology implementations or process improvement initiatives where iterative development and operational feedback should shape solutions, PMI-ACP validates knowledge of agile principles, Scrum, Kanban, and other adaptive methodologies increasingly relevant in logistics.

CAPM® (Certified Associate in Project Management): An entry-level PMI certification ideal for logistics professionals transitioning into project management roles or operational managers who oversee projects but don’t lead them full-time. CAPM provides foundational project management knowledge without requiring extensive project management experience.

Logistics-Specific Certifications

CSCP (Certified Supply Chain Professional): APICS’ flagship certification covering end-to-end supply chain management from suppliers through customers. For logistics project managers, CSCP provides critical domain knowledge about supply chain strategy, planning and execution, and supply chain improvement, helping you understand the operational context where your projects deploy.

CLTD (Certified in Logistics, Transportation and Distribution): APICS’ specialized certification focusing specifically on logistics operations, transportation management, and distribution center operations. CLTD deepens domain expertise in the areas where most logistics projects concentrate.

Quality Management certifications (Green Belt, Black Belt): Lean Six Sigma provides powerful process improvement methodologies highly applicable to logistics projects focused on operational efficiency, quality improvement, or cost reduction. The DMAIC framework (Define, Measure, Analyze, Improve, Control) complements project management methodologies by providing structured problem-solving approaches.

Future Trends in Logistics Project Management

AI and Machine Learning Integration

Predictive project management leveraging artificial intelligence will fundamentally change how logistics projects are planned and executed. Machine learning algorithms analyzing historical project data can identify risk patterns invisible to human analysis, predict which tasks are likely to overrun based on early execution signals, and recommend optimal resource allocation strategies.

AI-powered project management assistants will automatically flag schedule risks (“Based on current progress velocity, you’re trending 12% behind schedule for the carrier integration workstream”), suggest mitigation strategies drawn from similar past projects, and even draft communication updates for project managers to review and send.

Automated risk assessment tools will continuously monitor both internal project metrics and external factors, weather forecasts, port congestion indicators, supplier financial health, regulatory proposal tracking, alerting project teams to emerging risks before they impact project execution.

Sustainability and Green Logistics Projects

Environmental project constraints are evolving from “nice to have” considerations to mandatory requirements. Logistics projects increasingly must demonstrate carbon footprint reductions, circular economy principles, and environmental justice considerations. Project managers need new competencies in lifecycle analysis, sustainable procurement, and ESG reporting.

ESG reporting requirements mean logistics projects must track and document environmental, social, and governance impacts. A distribution center construction project must report embodied carbon in materials, a transportation optimization project must quantify emissions reductions, and a technology implementation must address electronic waste disposal.

Future logistics project managers will need to balance traditional constraints (scope, time, cost, quality) with sustainability constraints, requiring new tools, methodologies, and mindsets.

Blockchain and Supply Chain Transparency

Blockchain technology promises to enhance supply chain transparency and traceability, creating new project opportunities and challenges. Implementation projects involving blockchain consortia require navigating complex multi-party governance, interoperability standards, and data sharing agreements, unlike traditional single-organization technology projects.

Smart contracts on blockchain platforms can automate project milestone payments, enforce service level agreements, and create immutable audit trails, potentially reducing project administrative overhead while increasing accountability.

Autonomous Systems and Robotics

Automation project management becomes increasingly critical as logistics operations deploy autonomous mobile robots, automated guided vehicles, drone delivery systems, and autonomous trucks. These projects combine elements of software implementation, hardware integration, facility modification, safety compliance, and workforce transition, requiring project managers with unusually broad skill sets.

The human-robot collaboration introduces unique change-management challenges. Project managers must help warehouse associates transition from viewing robots as job threats to understanding them as productivity multipliers that handle repetitive tasks while humans focus on exception handling and problem-solving.

Conclusion

Project management for logistics represents a specialized discipline that combines traditional project management principles with the unique complexities of supply chain operations. As global supply chains grow more interconnected, technology-dependent, and customer-centric, the ability to successfully deliver logistics projects has become a critical competitive advantage.

The most successful logistics project managers master not just methodologies and tools, but the art of orchestrating change within live, operating supply chains that cannot pause to accommodate implementations. They balance technical requirements with operational realities, build coalitions across diverse stakeholder groups, and maintain focus on delivering measurable business value rather than simply completing tasks.

Whether you’re implementing warehouse automation, optimizing transportation networks, deploying new technology platforms, or redesigning distribution strategies, the frameworks, tools, and best practices covered in this guide provide a foundation for success. The key is adapting these principles to your specific organizational context while maintaining disciplined execution and continuous learning.

As you embark on your next logistics project, remember that project management excellence isn’t about following perfect plans, it’s about building resilient approaches that adapt to inevitable challenges while keeping stakeholders aligned and operations performing. Invest in developing your project management capabilities, earn relevant certifications, and learn from both successes and setbacks. Your ability to deliver complex logistics projects successfully will increasingly define your career advancement and an organization’s competitiveness in the years ahead.

Frequently Asked Questions

1. What is project management in logistics?

Project management in logistics is the application of project management principles, methodologies, and tools to temporary supply chain initiatives such as warehouse automation, transportation network optimization, technology implementations, or distribution strategy redesign. It differs from logistics operations management by focusing on unique, time-bound projects rather than ongoing daily activities.

2. Which project management methodology is best for logistics projects?

The best methodology depends on the project type. Waterfall works well for infrastructure projects with fixed physical dependencies. Agile excels for technology implementations where iterative learning improves outcomes. Hybrid approaches that combine both suit complex logistics transformations and diverse components. Critical Chain methodology optimizes resource-constrained multi-project environments common in logistics.

3. What are the biggest challenges in logistics project management?

The primary challenges include: managing projects within live operations that cannot stop for implementations, coordinating numerous external stakeholders with competing priorities, integrating new systems with legacy technology infrastructure, maintaining operational performance during transitions, and adapting to external disruptions like supply chain shocks or regulatory changes.

4. What tools do logistics project managers use?

Essential tools include project management platforms (MS Project, Smartsheet, Monday.com), collaboration tools (Microsoft Teams, Slack), business intelligence systems (Power BI, Tableau) for analytics, and integrations with operational systems like warehouse management systems (WMS) and transportation management systems (TMS) for real-time performance monitoring.

5. What certifications are valuable for logistics project managers?

The most valuable certifications include PMP® (Project Management Professional) for comprehensive project management frameworks, CSCP (Certified Supply Chain Professional) for logistics domain expertise, PRINCE2® for structured governance approaches, and Six Sigma certifications for process improvement skills. PMI-ACP® adds value for Agile logistics projects.

6. How is logistics project management different from general project management?

Logistics project management differs in its: requirement to execute within live operations serving customers 24/7, extensive external stakeholder ecosystems including carriers and vendors, vulnerability to real-time disruptions like weather or capacity constraints, integration complexity with physical operations and legacy systems, and need for specialized supply chain domain knowledge.

7. What skills do you need for logistics project management?

Critical skills include: leadership and cross-functional team coordination, supply chain and logistics operations knowledge, change management expertise to drive adoption, analytical and problem-solving abilities, stakeholder management across diverse groups, technical understanding of logistics systems, and risk management capabilities for dynamic environments.