The quality of a product is often the difference between a trusted brand and a forgettable one, and at the center of that difference is the Quality Assurance (QA) Manager. Far from a back-office role, QA leaders safeguard customer trust, reduce risk, and keep operations running right the first time. Depending on the organization, the title may be Quality Manager, QA Head, or Quality In-Charge, but the mission stays the same.

Real improvements are measurable. In one ASQ-published case study from a polypropylene extrusion facility, a Six Sigma project cut the scrap ratio from 1.19% to 0.60% and reduced total scrap by 55%, saving more than $300,000 annually, the kind of operational impact QA leaders are hired to drive.

Broader research aligns with this: studies of ISO 9001 quality-management systems link certification with stronger employee- and customer-related performance, reinforcing why organizations invest in rigorous QA leadership and systems.

In this guide, we’ll provide practical insights: key responsibilities, a ready-to-use job description template, manufacturing-specific duties, essential skills and KPIs, and career insights for 2025, supported by data and reputable sources.

Quality Assurance Manager- Job Description

The Quality Assurance (QA) Manager plays a critical role in helping organizations formulate and enforce quality standards, policies, and regulations for both employees and products. They analyze performance data, oversee audits, and develop improvement plans to ensure processes consistently meet compliance and customer expectations. A QA Manager is also accountable for identifying errors, inspecting procedures, and ensuring corrective actions are implemented.

An effective QA Manager should bring strong experience in quality control, quality management systems (QMS), and process improvement frameworks such as ISO 9001 or Six Sigma. The ideal candidate is not only skilled in detecting defects but also in driving long-term business success by embedding quality into every stage of the product life cycle.

|

Pro Tip for Employers: A well-written QA Manager job description should outline clear responsibilities, measurable KPIs (such as defect rate, first-pass yield, and audit scores), and the leadership expectations for the role. According to LinkedIn’s job description guidelines, top candidates look for both technical requirements and the strategic impact of the role. |

Also Read: Quality Control Inspector Job Description!

Roles and Responsibilities of Quality Assurance Manager

A Quality Assurance (QA) Manager does much more than check final products. They are the strategic backbone ensuring processes, people, and products align to achieve quality, compliance, and continuous improvement. Here are detailed real-world responsibilities (with data) that top organizations expect.

1. Establishing Quality Standards and Systems

A QA Manager’s first responsibility is to define what “quality” means for the organization. This involves creating, implementing, and updating quality management systems (QMS) aligned with frameworks like ISO 9001, IATF 16949, or GMP.

- Develop quality policies and standard operating procedures (SOPs)

- Ensure every department integrates these standards into daily work

- Review and revise policies to meet evolving regulations and customer needs

According to studies, companies that adopt certified QMS frameworks report significant improvements in both customer satisfaction and internal efficiency.

2. Data-Driven Process Improvement

QA Managers are expected to move beyond intuition and make decisions based on hard data. They track defect rates, First Pass Yield (FPY), and Cost of Poor Quality (COPQ) to uncover weak points.

- Apply tools such as SPC charts, Root Cause Analysis, and FMEA

- Lead Six Sigma or Lean initiatives to eliminate recurring issues

- Translate insights into corrective and preventive measures

3. Reducing Scrap, Rework, and Waste

Quality managers directly influence profitability by minimizing waste and optimizing resource utilization. Scrap and rework not only cost money but also harm sustainability and delivery timelines.

- Monitor scrap and rework costs as key KPIs

- Lead initiatives to bring down non-value-adding activities

- Collaborate with suppliers to improve incoming material quality

Case in point: RI-Matsol cut scrap levels from 15% to under 2% after investigating supplier quality, tooling, and material grades.

4. Ensuring Compliance and Regulatory Alignment

Compliance is non-negotiable, especially in manufacturing, pharma, and automotive. QA Managers conduct audits, oversee certifications, and ensure traceability across processes.

- Plan and execute internal and supplier audits

- Maintain certifications (ISO, FDA, CE, etc.)

- Implement CAPA (Corrective and Preventive Actions) for non-conformances

This role is especially critical when the stakes are high. Alcoa Power and Propulsion credited its process management approach with saving millions by reducing scrap and securing compliance consistency.

5. Leading Teams and Training Employees

Quality isn’t achieved in isolation; it requires a culture shift across the organization. QA Managers train employees and coach teams to embed quality into daily operations.

- Develop training programs for inspection staff and operators

- Promote awareness of quality standards across functions

- Build a culture where defects are prevented, not just detected

6. Acting as the Customer’s Advocate

QA Managers ensure that customer expectations are not just met but exceeded. Complaints, warranty claims, and field feedback are turned into actionable improvements.

- Investigate and resolve customer complaints quickly

- Feed lessons learned into design and production improvements

- Monitor complaint trends to reduce recurrence

LinkedIn’s job description template notes that “monitoring and analyzing key quality metrics to track product performance and identify areas for improvement” is a core expectation of QA Managers.

7. Reporting and Strategic Quality Planning

Finally, QA Managers connect quality data with business strategy. They provide executives with reports that show the financial impact of quality initiatives and recommend next steps.

- Present dashboards linking KPIs to financial outcomes

- Recommend strategic changes to reduce COPQ and improve efficiency

- Align quality strategy with long-term business goals

Emerging Skills of a Quality Assurance Manager

A decade ago, QA Managers were valued mostly for their attention to detail and use of checklists. In 2025, that will no longer be enough. With industries adopting automation, predictive analytics, and digital quality systems, QA leaders are expected to be strategists, technologists, and culture builders all at once.

At Siemens, QA leaders are already applying AI-driven predictive maintenance to reduce maintenance costs by up to 30% and significantly improve equipment availability. Their work is no longer about catching defects late but about preventing them early and enabling smarter operations.

So what emerging skills are shaping the QA manager role?

1. Domain fluency with digital depth

Beyond knowing the process, managers must now understand how IoT sensors, automated dashboards, and AI-powered tools are transforming production. In McKinsey’s Global Lighthouse factories, AI-led initiatives achieved up to 99% defect reduction in certain processes.

2. Human insight as a differentiator

While systems digitize, empathy still matters. QA managers must understand how defects or downtime affect customers.

3. The voice that influences

Quality cuts across design, supply chain, production, and after-sales. The best QA managers do not just report defects; they influence leaders by translating trends into risks, costs, and customer impacts.

4. Orchestration, not multitasking.

Instead of juggling endlessly, QA managers orchestrate priorities. Companies using digital collaboration tools have reduced scrap by ~25%, by enabling faster root-cause resolution and tighter supplier alignment.

5. Project leadership in transformation

Whether adopting robotics, ERP systems, or sustainability-driven standards, QA managers are often tasked with leading change. Projects with strong change leadership are 77% more likely to meet goals.

Salary and Career Outlook for QA Managers

The career path for a Quality Assurance Manager is steadily evolving. What was once seen as a mid-level operational role is now viewed as a strategic leadership position, especially as organizations compete on customer trust and compliance. Compensation reflects this shift, but it also varies by geography, industry, and experience.

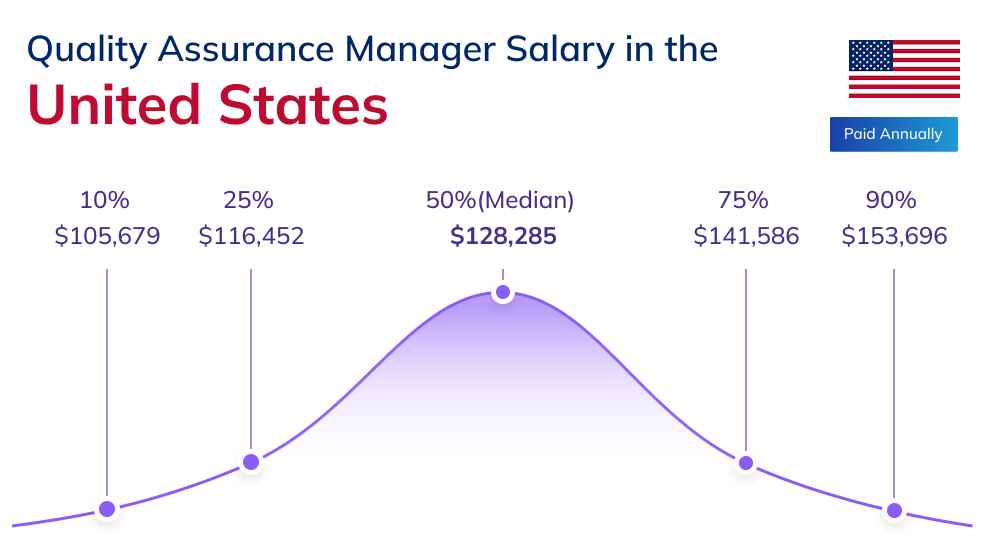

United States

According to Salary.com, the median annual salary for QA Managers in the U.S. is $128,285, with most earning between $105K and $153K, depending on region, company size, and industry. Managers in highly regulated industries such as pharmaceuticals, aerospace, and medical devices often command salaries at the higher end because of stricter compliance requirements.

India

In India, salaries scale differently. Glassdoor estimates QA Manager compensation between INR 14–31 lakhs per annum, with metro hubs like Bangalore, Pune, and Hyderabad paying at the upper end due to their concentration of tech and manufacturing firms. Companies in the automotive and electronics manufacturing clusters are also pushing pay upwards as they adopt digital quality frameworks and export standards.

Europe

In Europe, QA Manager salaries average around €60,000–€85,000 annually, though the range is wider in countries like Germany, where precision manufacturing and automotive industries set higher benchmarks. The demand for QA professionals with ISO/IATF certification expertise remains particularly strong in EU markets.

Career Growth Trajectories

A QA Manager role is rarely a career plateau. Professionals who excel in strategic quality planning, digital transformation, and cross-functional leadership often move into roles such as:

- Quality Head or Global QA Director – overseeing enterprise-wide quality systems.

- Plant QA Director / Site Quality Leader – managing end-to-end quality for large facilities.

- VP of Quality or Operations – taking on responsibility for compliance, customer satisfaction, and business performance.

Many QA leaders also transition laterally into Operational Excellence, Risk Management, or Regulatory Affairs roles, since their skills overlap with compliance and continuous improvement.

The Future Outlook

The future looks promising. McKinsey’s research on Lighthouse factories shows that companies leading in digital quality management are seeing up to 99% defect reduction in targeted processes. This trend increases the demand for QA managers who not only understand quality systems but can also effectively integrate AI, IoT, and predictive analytics into their organizations.

In short, the salary figures are competitive, but the real value is in how the role is expanding. A QA Manager today is a bridge between compliance and competitiveness, and those who embrace emerging technologies and leadership responsibilities are well-positioned to join the executive ranks.

Conclusion

Quality today is more than a function; it is a competitive advantage. As industries adopt AI, IoT, predictive analytics, and digital quality systems, QA Managers are expected to move beyond inspection and become drivers of strategy, compliance, and customer trust. Staying relevant in this evolving landscape means continuously upgrading skills, embracing new technologies, and leading teams with vision.

For professionals aiming to accelerate their careers, globally recognized Quality Management certifications and Lean Six Sigma Green Belt (LSSGB) certification are proven pathways. These remain among the most respected for building data-driven problem-solving skills.

By committing to continuous learning and applying these practices effectively, QA Managers can position themselves not only as guardians of quality but also as strategic leaders shaping the future of their organizations.