In today’s challenging business environment, customer satisfaction is crucial to staying relevant and profitable. Many global companies are implementing stream-oriented methodologies to maximize their growth and also to gain a competitive advantage over other organizations. Six Sigma is one such data-driven methodology that addresses crucial process variances and defects to eliminate waste. The design or structure is based on statistical and scientific data available to the customer.

Many might wonder why Six Sigma is having such a significant impact on organizations. The reason behind this is the methodology or approaches used in the system. The program combines thorough analysis, accurate decisions, and a concrete control plan that adds to the already existing process of quality control.

With the help of Six Sigma, any organization can find the loopholes that are causing a tremendous increase in expenditure on the product. To improve the quality of the product, the organization has to detect frequent errors that are taking place, which involves applying quality management best practices to nullify the mistakes and improve the overall quality of the product or service. Six Sigma’s adoption, it triggers a positive wave in the company, and all the other things start to change one by one.

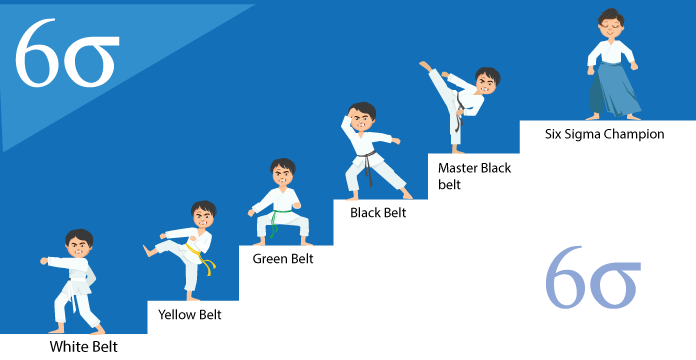

Business improvements don’t happen out of the blue, and they require a proper step-by-step system that should be strictly adhered to. The steps involved in Six Sigma are to Define, Measure, Analyze, Improve, and Control. To have complete knowledge of how Six Sigma benefits enterprises globally, we need first to understand the various Six Sigma roles in an organization. Six Sigma has a color classification system that distinguishes different training levels and hierarchical structures. Each Belt has its significance for the organization. Each ranking’s scope is vast and helps its way to take the company to the next level.

Six Sigma Belt Rankings

To get to the highest level of certification, one has to achieve excellence in five belts. The rankings of the Six Sigma belts are as follows:

- White Belt

- Yellow Belt

- Green Belt

- Black Belt

- Master Black belt

- Six Sigma Champion

This type of stratification is deployed with colors to recognize the proficiency with ease and helps the organization to segregate the members based on their belt color.

Six Sigma Champion

As the name suggests, these are the champions of the Six Sigma certification. This phase of Six Sigma is very crucial for the entire initiative. After acquiring all the skills, they pass them on to the low-tier members that are the Master Black Belts and Black Belts. The Six Sigma Champions fill the gap between the organization’s management and Black Belts. They lead the project teams and are responsible for categorizing correct objectives. They are entitled to deploy appropriate measures to attain success in implementation plans. They pass on leadership skills that they possess, and they do reviews of Black/Green Belt professionals. Product performance and project identification are some of the most critical roles for a Six Sigma Champion.

Six Sigma Master Black Belt

After Six Sigma Champion, the next in the hierarchical structure is the Master Black Belt, which has a good grasp of Six Sigma philosophies and principles. To be at this level requires a great deal of determination and leadership skills. They are acquainted with proper skills that help manage DMAIC models. They work in a diverse environment to lead the initiative of analysis and performance assessments. The tools that are provided help in process improvement and perform on a higher level in enormous projects for the organization. When Master Black Belts are not on any project, then they teach other members at lower levels of the hierarchy. The real-life applications of the Master Black Belt deal with transportation, overproduction, and inventory defects.

Six Sigma Black Belt

Just under the guidance of the Master Black Belts come the Black Belt professionals. They monetize the organization with their assets like having command of process development. The revenues are accurately measured, and for that, a Black Belt professional use statistical analysis techniques. Some of the highly valued skills learned from the Six Sigma Champion are leadership attributes. Industry-based case studies are involved in this certification, and skills gained from this apply to real-life situations. The customer’s feedback is used to calculate the defects and amount of waste generated. Critical Skills that the Black Belt professionals are proficient in are statistics and engineering.

Six Sigma Green Belts

This category in Six Sigma is considered the heart of it all and does the most work accounting to 20-50 percent of all Six Sigma projects in an organization. The methodology and principles are followed to perfection by the Green Belt members. When it comes to improving quality and project management, they are the experts. They lead most of the research, and narrowing down the defects is processed. Green Belt professionals can communicate with other members of the hierarchy. Usually, the Green Belt professional takes up quality assurance roles, and the implementation of continuous improvements is performed throughout the project. The Yellow Belt professionals are trained by the Green Belts to lead a more successful journey in handling and being part of Six Sigma projects. The projects undertaken by the Green Belt professionals are mostly minor for the organization.

Six Sigma Yellow Belt

The Six Sigma Yellow Belt is an entry-level certification that helps professionals to understand the essential tools used in Six Sigma projects, best practices, and key concepts. It is one’s duty to find the origin of the problems and map the traversal of defects in the manufacturing process. These are called “Root Cause Analysis” and “Value Stream Mapping” in terms of Six Sigma. They must be able to work under short deadlines and follow instructions provided by the project managers. Fundamental tasks are allotted to the Yellow BeltBelt certified individuals, and they are data mining, organization tasks, and roles in the statistical field. The Yellow Belt follows the guidance provided by senior and more experienced Six Sigma professionals. The PDCA curriculum navigates the individual to the right places for mentorship.

Six Sigma White Belt

This tier in Six Sigma is considered the lowest in which the individuals are mentored for the necessary tools and methods required to perform management tasks. All the project leaders are from higher tiers and are highly qualified with different Six Sigma levels. Their structure in DMAIC is limited to a tiny portion. Many even consider this tier not to be a part of Six Sigma. Augmenting customer satisfaction and taking feedback are done daily. To improve quality and reduce costs on resources is the main idea. A clear grasp of Lean methodologies is the main objective of the certification. Individuals need to have a proper understanding of the methods the company uses for movement in manufacturing.

Six Sigma Orange Belt

In the hierarchy of Six Sigma, the Orange Belt is the least, but it has its identification and functionality. Most of the top-tier members view the Orange Belt as the apex part of Six Sigma. They do not act as the lead of Six Sigma projects, but they work in supporting roles. An Orange Belt expertly manages the quality change. An individual with this level of certification should be open to new ideas and try to innovate. There is constant development in the workplace, which, in turn, helps the member to connect the knowledge obtained and how it is related to Kaizen. Identifying the income streams and mapping them back to their origin is accomplished with the help of Orange Belt professionals.

To Summarize

Not everyone has a good grasp of every aspect of Six Sigma, but what is essential is to remember that it is an ongoing process and not a static chain. So, deploying every technique one could think of is vital, and experimenting also plays a crucial role in having amazing breakthroughs. Many things play critical roles in this process. One of them being higher officials or top-ranked professionals participating more in the deployment stage. The product launch and other events are supposed to be overlooked by these people. The next thing to maintain success relies on project selection. One must not randomly select any project. We have to consider different factors like scope, margins, and resources available at our end. This will, for sure, demonstrate early wins for the organization.

It is ok to let an external consultant join the group when there is a lack of diversity. A new environment will be created, and the entire vibe changes when the leader is different. When talking about mentorship, it should be more about transforming people into knowledgeable assets by ensuring they undergo formal quality management training. This way, everyone stays engaged and committed to the organization’s goal. The last in the process is to recognize and encourage new talents in the organization. Rewarding teams for their efforts motivates them to pursue higher levels in the ranking, and that eventually will benefit the organization.